Mill-Turn

Mill-Turn

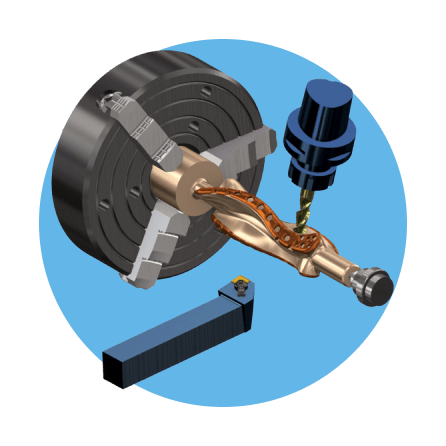

Mastercam Mill-Turn programming software streamlines high-power multistream machine centers for increased performance and safety. These multitasking CNC machines reduce multiple setups, manual part handling, redundant fixturing, and idle time for improved productivity in manufacturing.

Product Overview

Using Mastercam’s proven milling and lathe toolpaths, this software simplifies the programming process for mill-turn machines with job setups keyed to the exact machine in your shop.

- Optimization, synchronization, and visualization in a single platform.

- Automation to easily manage complex operations between multiple machine data streams.

- Efficient milling, turning, and drilling operations with fewer setups at high speed.

- Program simple lathes in addition to complex machines.

This lathe mill combination programming software provides a set of routines to program complex parts and test your cutting strategies in a single environment—before your stock is on your multitasking machine. You can use Mill-Turn to machine parts without fear of costly collisions or machine damage.

- Automated job setup

- Intelligent, stock-aware toolpaths

- Powerful Gantt- or Tree-style synchronization

- Intuitive part handling tools specific to your machine

- Full machine simulation with accurate visual feedback

- Powerful multiaxis cutting

Mastercam Mill-Turn provides a custom machining environment in which the machine configuration and limits are captured and displayed graphically to ensure safety and quality.

Get Started

If you are looking to find your Channel Partner, click on the link below.

Features

CAD for CAM

A full design package based on a machinist’s needs, including wireframe, surfaces, and solids design; open most CAD files in Mastercam to access modeling and prep tools for CAM programmers to get parts on and off machines quickly.

Advanced Technology

Mastercam’s proven toolpaths, intuitive part handling, automated job setup, 3D tooling support, customized milling tools optimized for mill-turn machining, deburring, support for 2- through 5-axis toolpaths, multiturret, multispindle, and more—all managed in a single machine environment.

Advanced Toolpaths

Detect collisions between your stock, tool, and machine components before sending code to your machine tool. Machine Simulation is a safe way to prove out 3-axis, 4-axis, or 5-axis toolpaths to make clean, efficient, and accurate programs.

Mastercam Code Expert

Optimize machine movement and synchronization between turretsand spindles with this state-of-the art interface to generate accurate and efficient code.

Extend tool life with proprietary toolpath strategies that maximize material removal rate and reduce cycle times.

Flexibility

Mastercam Mill-Turn allows you to have a complete post, additional tools made for those machines like pinch and balanced turning, and ease of use for twin spindle, twin turret, and B-axis head machines.

Benefits

As a result of being part of the Sandvik network, Mastercam Mill-Turn users get the benefits of industry-leading technology like PrimeTurning™ automated toolpath strategies and CoroTurn® tools.

Add Ons

Case Studies View all

3D-Machine, Inc.

New CAM toolpath cuts hoist drum production time by 83 percent Before using Mastercam Lathe Custom Thread toolpath, producing a hoist drum—including machine set up, tooling, and machining—took at least 40 hours. With the CAM toolpath, 3D-Machine, Inc. produced the part in just seven hours. Quick Facts Product Used: Mill, Mill-Turn, Lathe, Multiaxis Industry: Tool…

Achates Power

Complex Machining Replaces Casting for Two-Piece Components in Piston Prototypes Achates Power in San Diego, California, uses Mastercam to create prototype parts for an eco-friendly, gasoline compression ignition, opposed-piston engine. The collaborative research was the work of Achates, Argonne National Laboratory, and Delphi Technologies. It was produced using funding from the U.S. Department of Energy’s…

Mastercam Community

When you choose the world’s most widely used CAM, you gain benefits beyond the technology driving our software. Our global community of Mastercam users, experts, educators, and enthusiasts helps you get the most from your investment.

FAQs

A mill-turning machine performs subtractive manufacturing, where material is removed through strategic cutting techniques. On a mill-turning machine you have the capabilities of a mill, where the tools move around a piece of stationary stock material, combined with the capabilities of a lathe, where the tools move on a spinning piece of stock. A CNC mill-turning machine is capable of cutting parts as programmed by a CAM software like Mastercam.

CloseA CNC mill-turn machine is programmed like all computer numerical control machines, with a CAM software. Software such as Mastercam is used to create efficient machine motion using G-code to program the CNC mill-turning machine and automate the manufacturing process.

CloseCNC milling is a subtractive manufacturing process where the tools move around a stationary piece of stock material that is held in place with a variety of fixturing options. In CNC turning, material is similarly removed from a piece of stock material, but instead of being stationary, it is spinning in a lathe assembly.

CloseIt is difficult to identify a disadvantage to a milling machine unless your manufacturing process would benefit from a different type of machine altogether, such as a lathe, mill-turn machine, or Wire/EDM machine, for example. This cost of investing in a CNC milling machine may seem like a disadvantage compared to a manual mill. However, it is likely the added machining capability and increased productivity and efficiency benefits will so quickly compensate for the initial investment that the cost is not truly limiting as a disadvantage.

CloseMill-turning machines introduce complexity not seen in many other milling machines or lathes. Mill-turning machines often include multiple turrets with different tools, some of which can engage the part at the same time. For this reason, the most important aspects of safe and efficient mill-turn programming are 1) robust mill and lathe programming techniques, and 2) the ability to properly synchronize tool motion from multiple locations.

CloseCNC mill-turning software eliminates errors that can occur when manually programming a CNC mill-turning machine. It also allows adaptability and offers methods of precision machining that are impossible through manual programming.

Close