Local Career Center Produces World-Class Machinists

Vantage Career Center doesn’t let its rural location stand in the way of providing a world-class precision machining education to its students. Instead, it leverages partnerships with technology providers and state and local governments.

The Challenge

Ensuring Vantage Career Center students graduate with robust experience and cutting-edge manufacturing skills.

The Solution

Through its partnership with Mastercam, students learn CNC programming for modeling, creating, and verifying G-code, optimizing toolpaths, and more.

Benefits

- Ability to create and edit toolpaths.

- Use Dynamic, Verify, and Backplot to test and validate toolpaths.

- Students use Mastercam Design to draft parts.

- Machine Simulation is used to prove toolpaths, detect collisions, and test tool cutters.

Project Details

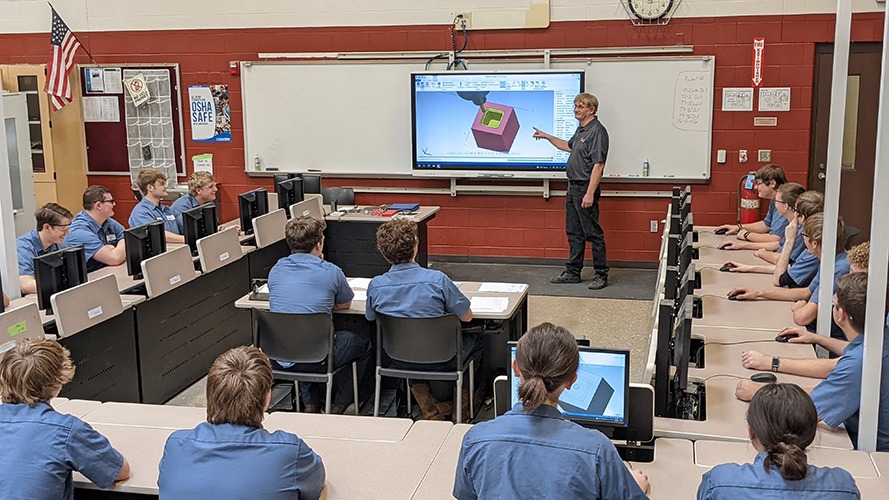

In his own words, the school where Larry Ray teaches precision machining is in the middle of nowhere. But manufacturers in the region know exactly where to find Ray and its students in Van Wert, Ohio.

At least 20 companies a year contact the school, interested in recruiting or working with students.

At Vantage, high school juniors and seniors in the precision machining program spend half the day in the classroom and half in labs, learning everything required to become an apprentice machinist. Upon graduation, students earn their high school diploma, apprentice certificates, and OSHA 10 safety certification.

Juniors start with manual machining to acclimate to the machining environment. “For many of these kids, this is their first exposure to manufacturing,” said Ray.

Seniors start with manual programming and G-code. During the following semester, students learn CAD/CAM programming using Mastercam, and pre-programmed prints to understand how the software functions.

Students move quickly from 2D drawing to 3D rendering to creating and editing toolpaths using Verify and Backplot. These Mastercam modules simulate the entire machining process as it is programmed so errors and collisions can be corrected in programming.

The school also uses Mastercam software as a drafting program. “Since Mastercam Design is included in our suite, we use it for drafting,” said Ray. Mastercam Design lets users create models from scratch or import models from other programs.

Ray has several practice projects baked into his curriculum to teach students how to use the machines and software. He takes a few of the students’ versions of the projects and machines them. The class then compares chip removal, machine speed, and part accuracy.

“We do that using a Dynamic toolpath first,” said Ray. “Then we run the parts on a machine to compare the speed and efficiency of each part. I do that to teach students that how they approach a part matters.”

Students often hone their skills fulfilling requests from local communities and companies. In one such project, seniors from the Precision Machining, Industrial Mechanics, and Carpentry schools joined forces to create railings for an elevated walkway in a nearby community.

By the end of their senior year, students bring everything they learned together to plan and execute senior projects. Every senior conceives, designs, and machines the project by themselves. Past projects include a working grandfather clock machined from aluminum, and parts for a competitive midget car.

“When they start creating and verifying their toolpaths in Machine Simulation, I see the light come on,” said Ray. “They stop thinking about each part and start thinking about their entire assembly.”

Mastercam Machine Simulation creates a model of the cutting process users can follow in real time. Users can detect collisions, test filtering scenarios, and test tool cutters before sending final code to the machine.

One student created salt and pepper shakers. She was verifying her design in Mastercam and realized the parts were not threaded correctly. She was able to fix the problem, saving herself from poorly machined parts, a bad grade, and a lot of spilled salt.

Quick Facts

- Product Used: Design, Educational Suite

- Industry: Education

“When they start creating and verifying their toolpaths in Machine Simulation, I see the light come on. They stop thinking about each part start thinking about their entire assembly.”

Larry Roy, Precision Machining Technology, Vantage Career Center, Van Wert, Ohio