Job Shop Gains Production Boost with CAD/CAM Software

Established in 1997, Grayco Machine Ltd., in Leduc, Alberta, Canada, manufactures parts for the agricultural and oil industries. Using Mastercam as a robust CAD/CAM platform for manufacturing efforts, the company specializes in producing pinions and gears for pump jacks as well as wireline winches for oil drilling rigs.

Quick Facts

Product Used: Wire, Lathe, Mill

Industry: Heavy Industry, Energy, Job Shop

Project Details:

- The Challenge: Achieving healthy production rates and product quality through times of economic uncertainty.

- The Solution: Mastercam, the most widely used CNC software for CAD/CAM operations

- The Benefits:

- To create complex part geometries for gears, CAM software generates gear G-code, tooth profiles and shapes.

- From basic 2-axis contouring to complex 4-axis motion, Mastercam Wire software supports powerful wirepaths and efficient cutting techniques.

- Wirepath verification tools ensure that toolpath motion achieves intended outcomes, minimizing roughing.

- Collision checks allow programmers to determine when tool changes are necessary and to preview part finishes.

- CAM software offers the flexibility to manufacture a variety of part geometries and sizes.

Despite ongoing volatility in the oil industry, the jobber shop is staying afloat thanks to the vision of its owner, Graham Peterson. A Red Seal journeyman machinist and longtime proponent of machining and apprenticeship programs, Peterson understands the need for skilled machinists. All Grayco employees are highly skilled Red Seal journeyman machinists well-versed in both manual and CNC machine operations.

Grayco’s 9000-square-foot facility houses manual and CNC mills and lathes, EDMs, and Sykes Herringbone-gear cutters. Lately, the wire EDM has been kept especially busy.

“We use the wire for doing internal and external splines and a lot of gear teeth,” said Peterson. “These parts are programmed with CAM software because we use it to generate all the profiles.”

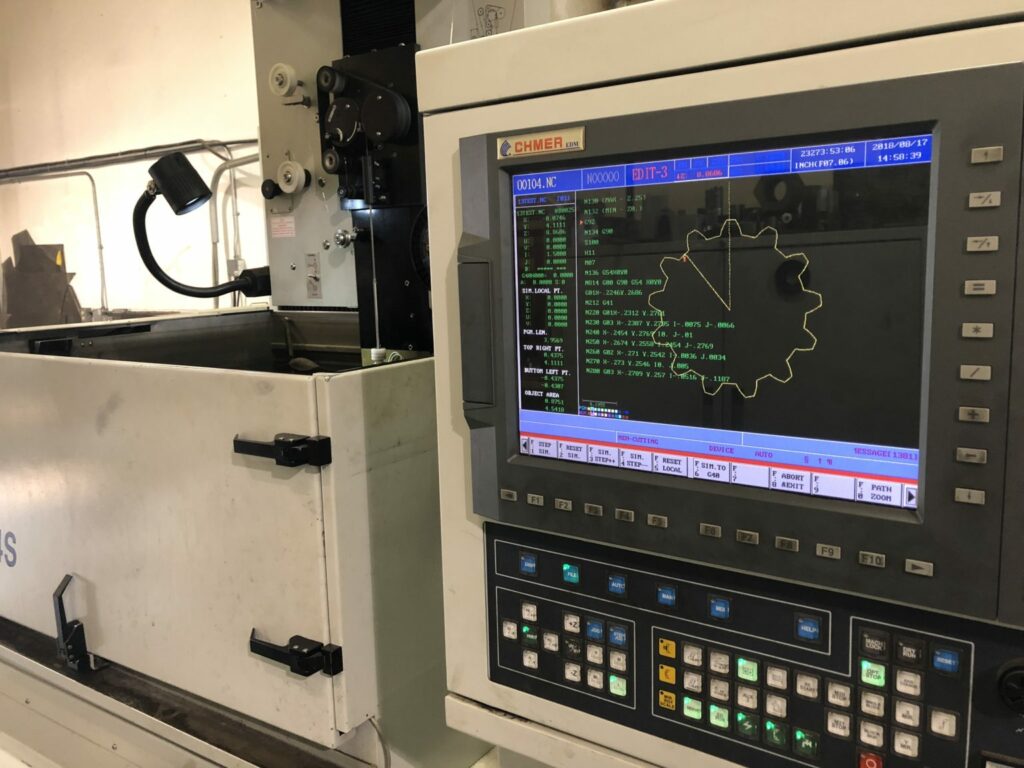

To manufacture gears, programmers use a wire EDM coupled with CAM software from Mastercam. From basic 2-axis contouring to complex 4-axis motion, Mastercam Wire software supports powerful wirepaths and efficient cutting techniques. Full 3D CAD modeling, automatic lead-in and lead-out strategies, and streamlined multiple-part cutting are features of the flexible software package. Wire software permits control over wire motion, angle, entries, exits, and more. File tracking and change recognition allow for simple programming and reprogramming. Job elements can be modified and wirepaths updated without restarts.

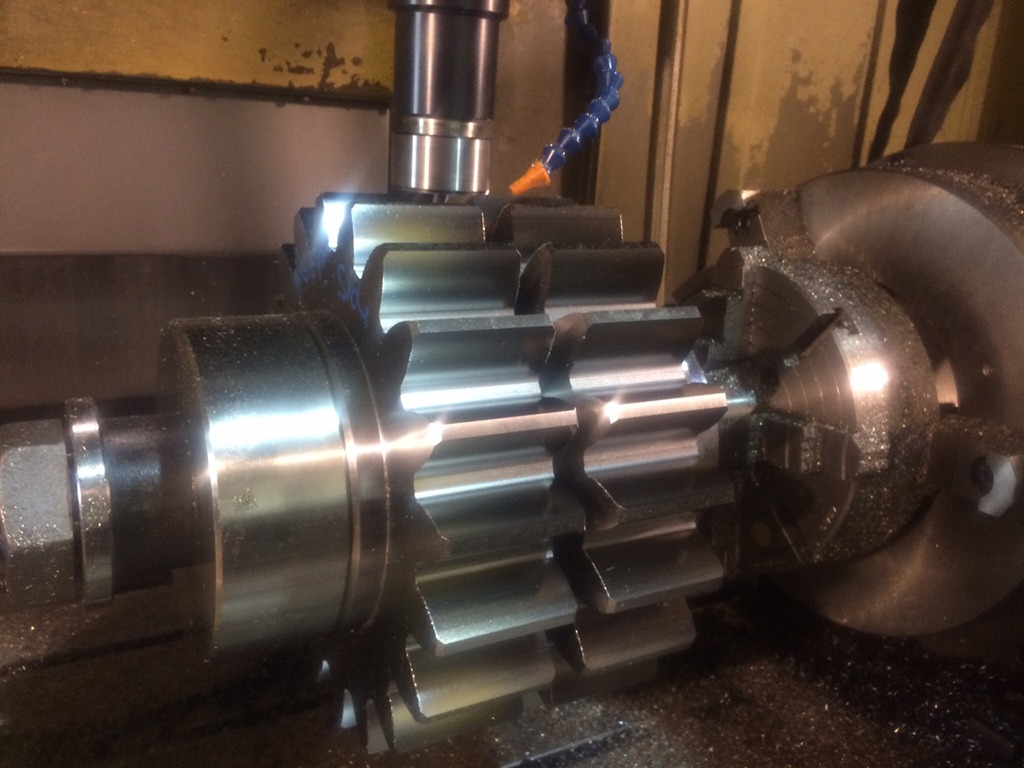

Sykes Herringbone gears are part of Grayco’s gear production. To create complex parts geometries, programmers rely on CAM software to generate gear G-code, tooth profiles and shapes.

“We’re using the software almost exclusively to program our machines,” said Peterson. “We’re getting into more and more difficult programs and part profiles. We can’t do it by hand anymore.”

To produce intricate part shapes, programmers rely on wire EDMs and the software that runs them. Mastercam’s Wirepath verification tools ensure that the toolpath motion achieves intended outcomes. In the case of Grayco gears, roughing is minimized. Usually, one rough pass and one finish pass are all it takes to complete the gear-making process. Surface finish tolerances of 64 Ra (roughness average) to 8 Ra are achieved.

“Mastercam helps us achieve a very accurate wirepath, especially on gear teeth,” said Jerry Deneve, Grayco Machine Red Seal journeyman machinist and CNC programmer. “We can get right down to grinding tolerances with the wire EDM and meet surface finish requirements with the help of the software.”

Turnaround times are a driving force here. Incoming work requires one-up or two-up part production. A customer idea goes from pad and paper, through Mastercam and into the finished part within a short timeframe.

“Some of the jobs we do, you just can’t program them longhand with a notepad,” said Peterson. “You need Mastercam to come up with those kinds of profiles, shapes and programs for the EDM.”

CAM software offers Grayco the flexibility to manufacture a variety of part geometries and sizes. If a piece is too large to fit on a machine, for example, an operator can work on one corner of the part at a time. He can program that corner, rotate the part, turn the model with Mastercam, re-post it, and go again.

Grayco contracts out surface modeling of its herringbone gears but plans to move production to milling machines. Current mill feeds are 200 hundred inches per minute; Grayco plans to purchase a machine that can accommodate 300 surface feet per minute with 20,000 RPM speeds to achieve required surface finish accuracy.

“We know that’s where we have to go,” said Deneve of updating the job shop. “We’ve done it nine ways to Sunday with the old machines but now we have to get modernized with the surfaces and 3D modeling to move to a different level.”

Since using Mastercam, Grayco has made better, more complicated parts at a faster pace. Modernization of this small but mighty job shop is possible thanks to the benefits provided by CAM software.

Customer Quote

“Some of the jobs we do, you just can’t program them longhand with a notepad. You need Mastercam to come up with those kinds of profiles, shapes, and programs for the EDM. And it goes back to being a jobber shop trying to do things quickly.”

— Graham Peterson, Owner, Grayco Machine Ltd., Leduc, Alberta, Canada