Hybrid Teaching Model for Manufacturing Curriculum Finds Success

For many years, the Precision Machining Technology program at Texas State Technical College has provided area students with a comprehensive CAD/CAM curriculum valued by the region’s manufacturing companies. With the advent of COVID-19, the pressure was on to overcome the social distancing requirements mandated by the pandemic while continuing to graduate skilled men and women into the workforce. When it comes to learning in the time of COVID, Tim Hemesath and his associates at Texas State Technical College have created a curriculum for success.

Quick Facts:

- Product Used: Mastercam Educational Suite, Dynamic Motion

- Industry: Education

Project Details:

- The Challenge: Develop and integrate a CAD/CAM program that would permit students to observe the safety requirements raised by COVID-19 while receiving the education they have come to expect from the college.

- The Solution: Mastercam Education Suite—CAD/CAM software for schools with Dynamic Motion toolpaths.

- Benefits:

- Provides program flexibility for teachers

- Students find Mastercam easy to grasp and use

- Permits combined in-school and at-home curriculum

- Provides students with the skills needed by industry

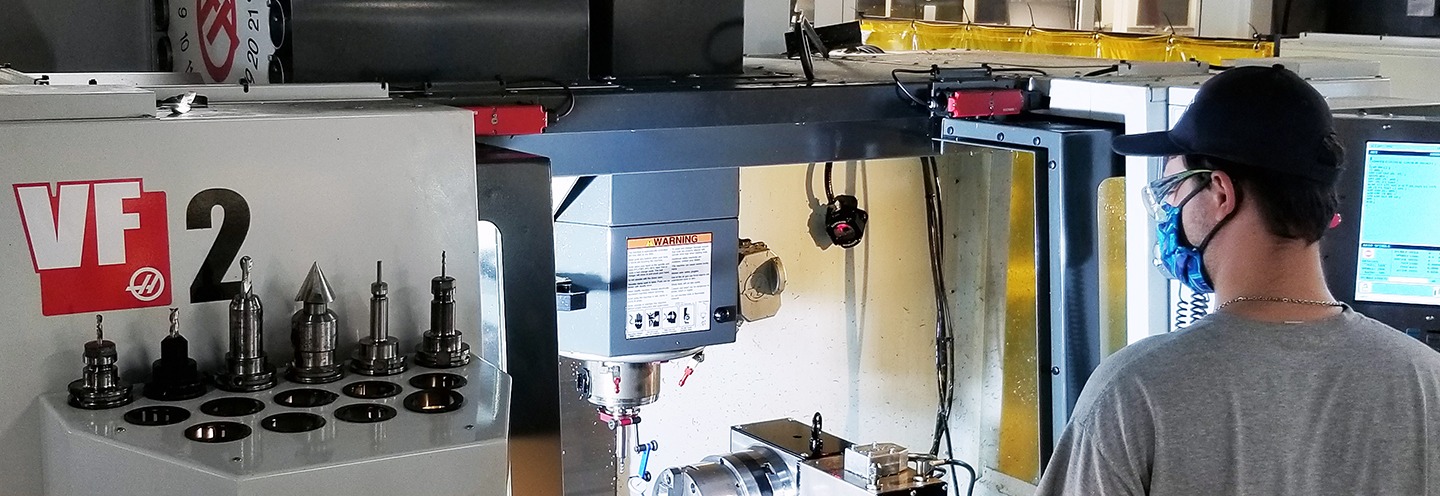

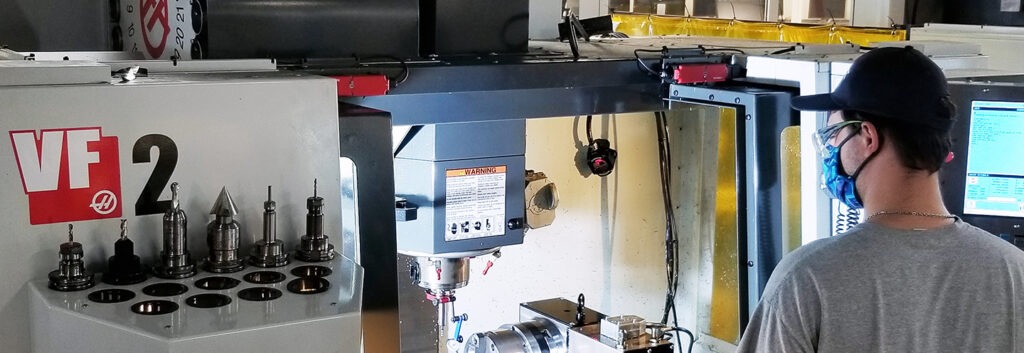

In spite of the social distancing requirements that resulted from COVID-19, the Precision Machining Technology program at Texas State Technical College (TSTC) just north of Austin has been able to develop a hybrid solution to keep the machines humming and students learning throughout the pandemic. “We all realized pretty quickly that we had to work out a way to bring the students into the lab,” said instructor Tim Hemesath. “When it comes to machine tools, it’s just like learning to ride a bicycle. You’ll never learn just by watching someone else do it. You have to get up on that bike and ride it yourself.”

As for the machine tools at TSTC, in addition to manual machines they have a full complement of Haas® CNC machining and turning centers. Because so much of the program centers on learning CAD/CAM systems, the lab includes many seats of Mastercam.

“We split the class of twenty-eight students into two groups of fourteen to alternate in-home and in-lab days,” said Hemesath. “They can do a lot of their CAD/CAM practice on their laptops at home, and on the days they come into lab, we all wear our face masks and practice social distancing. In the CAD/CAM area, we can plug the laptops and individual computer seats into a large screen so, again, we’re socially distanced.”

After learning manual machining procedures in the first semester to get a feel for cutting metal, students in the second semester get into the fundamentals of CNC controls. “Then we go into programming some 2D parts,” said Hemesath, “so they can understand the machine language, and they’re able to troubleshoot the program at the controls. It’s the start of a good understanding of the benefits of automated manufacturing.”

In the following semesters, the students really get into the “nuts and bolts” of CAD/CAM. “Their designs are imported into Mastercam to create the toolpaths that will be followed by the machine tools. I began using Mastercam for toolpaths back in 1999 in the various industries I worked in, and it’s the software I use with my students. It makes sense to teach them the software they’ll probably be using once they graduate. To start, I set them up with the user interface. They click on the Mastercam icon and determine if the part is going to be a mill part or a lathe part, or both, and which operation needs to be done first to get the part complete and to specification.”

“We also go into drafting, the views, the grids, and show the axes,” he continued. “The WCS (Work Coordinate System) with Mastercam’s Dynamic Motion machining goes over really well with the students. They can create a cross-section of a part, rotate it to the correct orientation, and then choose that plane in their parameter folder for the toolpath manager.”

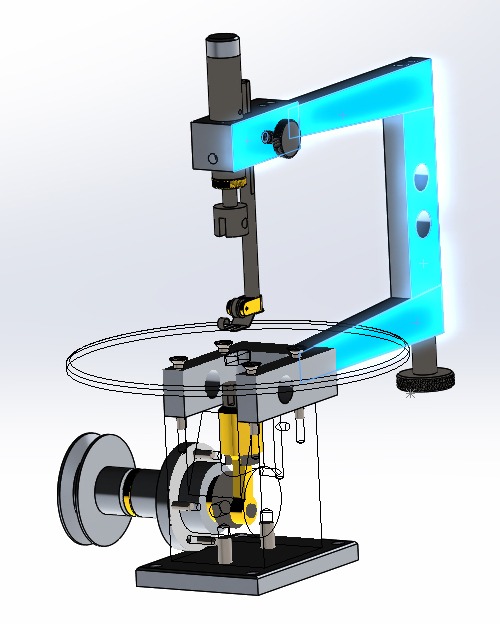

In the fourth semester, everything is brought together in a Machine Design course that Hemesath said is a “capstone” course for the students. “They are put together into project groups, and they decide who will be the project manager, the designers, and the programmers. They come up with ideas, based on their various hobbies, for complex assemblies. When you consider the fifteen-week time constraint we have to get capstone project parts completed, Mastercam has really allowed us to nail it. Mastercam’s Dynamic Motion machining features result in parts being made quickly and accurately by the students, while giving us a substantial saving in tooling. I have to say that without Mastercam, a lot of the projects the students depend on for their capstone grade just wouldn’t be able to be completed.”

Leaving TSTC with either an associate degree or certificate in Precision Machining Technology, graduates quickly earn jobs within the many manufacturing companies in the area. “We have ninety-five percent placement success,” said Hemesath, “with many of our students being offered jobs even before they graduate.”

Customer Quote

“Mastercam’s Dynamic Motion machining features result in parts being made quickly and accurately by the students, while giving us a substantial saving in tooling. I have to say that without Mastercam, a lot of the projects the students depend on for their capstone grade just wouldn’t be able to be completed.”

—Tim Hemesath, Instructor, Precision Machining Technology Program, Texas State