Ariel Taps CAD/CAM’s Full Power Through Training

Ariel Technologies, with a legacy that spans decades, continues to place an emphasis on employee and customer education. Part of its state-of-the-art training facility has a space dedicated to Mastercam CAD/CAM software.

The Challenge

Instruction with an eye toward the reduction of hand-programming.

The Solution

Mastercam, the most robust CAD/CAM software for machining applications.

Benefits

- Employee and customer training meet modern standards.

- CAD/CAM software accelerates the training timeline.

- Technology helps build a more-equipped workforce.

Project Details

When Jim Buchwald first began building gas compressors in his basement in the mid-1960s, he probably could not have imagined what the Ariel Corporation would eventually become. Today, it is the world’s largest manufacturer of separable reciprocating natural gas compressors.

In 2017, Ariel opened a massive, modern training facility on the campus of its world headquarters in Mount Vernon, Ohio which houses 12 classrooms and meeting rooms, three training labs, a theater, and an interactive atrium.

The company employs hundreds of machinists and operates more than 700 machine tools spread over one million square feet of factory floor. To develop its CNC programs, Ariel’s software of choice is Mastercam CAD/CAM software.

To climb the Mastercam learning curve, Ariel began crafting an 11-module training course covering the fundamentals. Ariel then outsourced the more advanced coursework to Mastercam Channel Partner, FASTech Inc. (Findlay, Ohio). FASTech has worked closely with Ariel over the years to troubleshoot and develop targeted programming solutions for new part designs and new or repurposed machine tools.

“FASTech was ideally suited to produce a tailored training program for us,” said Phillip Ott, Ariel’s staff group leader of technical training. “We want to focus on the Mastercam tools that directly apply to our parts machining workflows.”

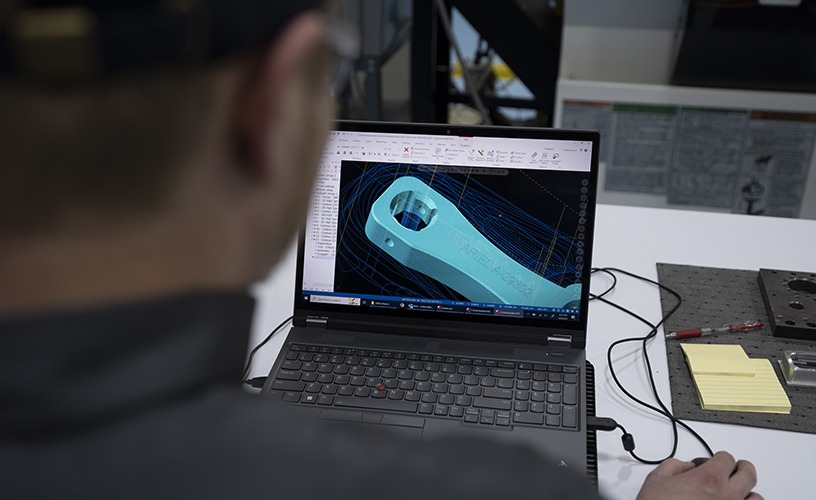

Instructional design complete, Ariel rolled out a 15-week Mastercam Training Workshop for an initial class of 12 company engineers and machinists. While classes were instructor-led, this was an authentic hands-on workshop. Classes were held in the company’s CNC Programming Lab tucked inside Ariel’s interdisciplinary Training Center. The Programming Lab has 16 dual-monitor computer workstations featuring high-performance CPUs running Mastercam software.

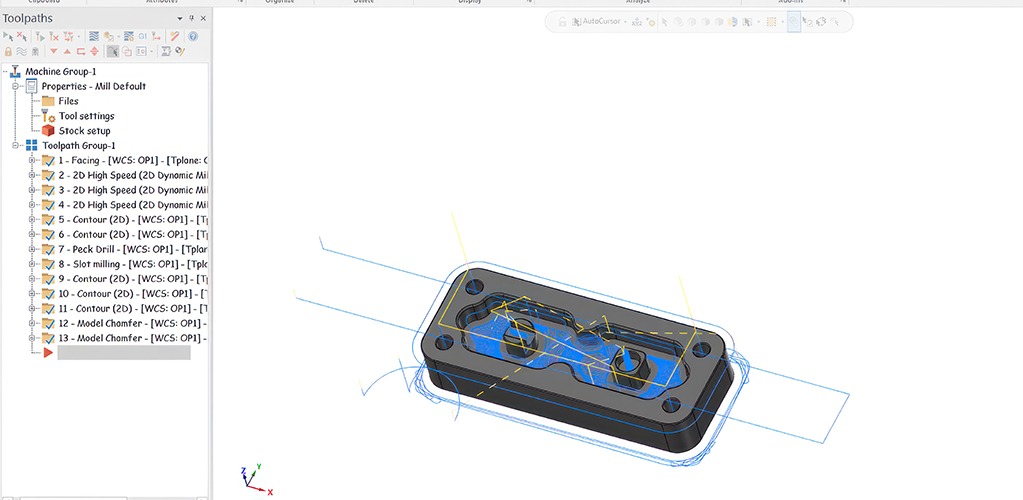

Training topics range from 3D modeling in CAD to functional setups in CAM, and from building tool assemblies to creating Dynamic toolpaths. Ariel and FASTech instructors teach the Mastercam Training Workshop in tandem, with Ariel taking the first 11 weeks and FASTech covering the last four.

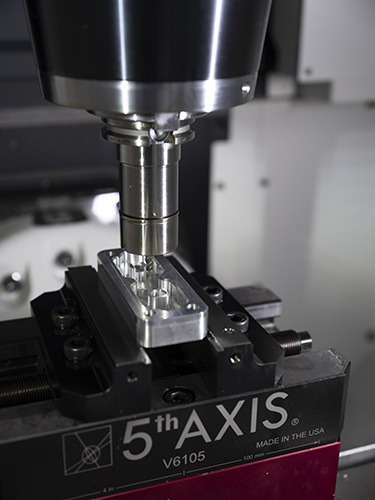

For the final exam, students are handed a drawing, a workpiece, and all pertinent specs for a finished part. They are tasked with creating a CNC program and then post it to one of the machine tools in Ariel’s Machining Lab. Students complete the assignment by machining the final part.

Ariel considers its Mastercam Training Workshop as the first installment of a broader training curriculum envisioned for its employees who will move the company forward in CNC programming. At Ariel, moving forward means looking to the future while honoring the past.

“We’ve been programming the same way for a long time; it’s second nature,” said Ott. “Learning to program a new way comes with a high degree of difficulty. Similarly, going mainstream with Mastercam across Ariel’s corps of machinists and engineering support team is a sizeable training effort that will be ongoing. The results so far have been clearly worth the effort.”

Quick Facts

- Product Used: Mastercam 2025 Educational Suite

- Industry: Metalworking, Education

“We’ve been programming the same way for a long time; it’s second nature. Learning to program a new way comes with a high degree of difficulty. Similarly, going mainstream with Mastercam across Ariel’s corps of machinists and engineering support team is a sizeable training effort that will be ongoing. The results so far have been clearly worth the effort.”

Phillip Ott, Staff Group Lead of Technical Training, Ariel Corporation, Mount Vernon, OH