CAD/CAM Instruction Unlocks Future for High School and Technical College Students

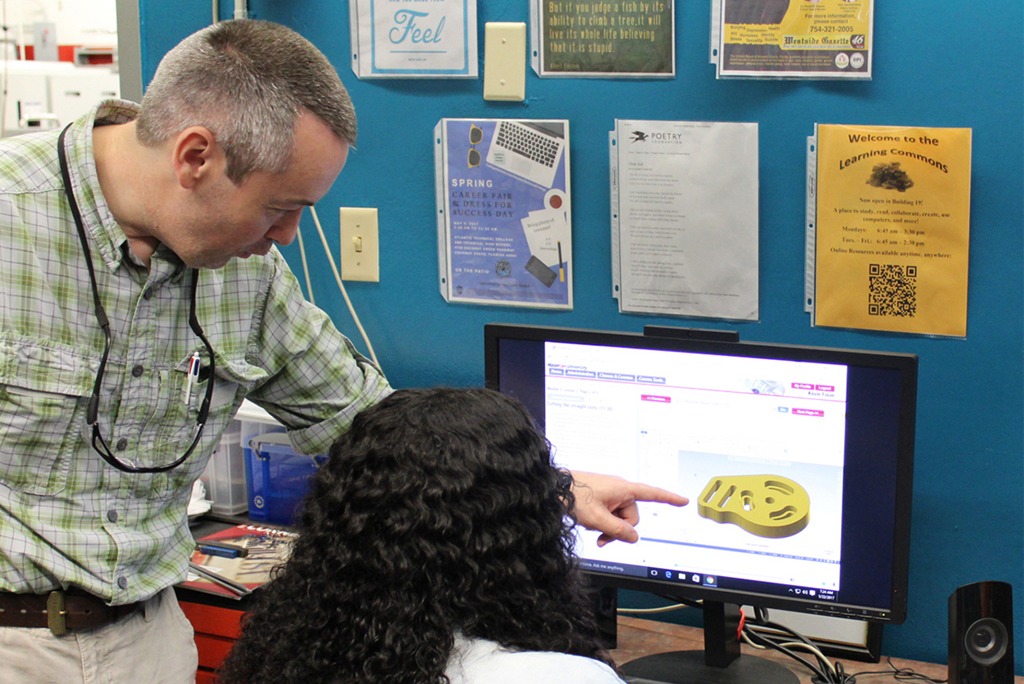

Known in the Coconut Creek, Florida, community as ATC, the combined facilities of Atlantic Technical College and Technical High School are using the teaching of Computer-Assisted Design (CAD) and Computer-Assisted Manufacturing (CAM) to propel interested students toward rewarding careers in today’s world of factory automation. Kevin Finan, Instructor in the Machining Technologies Program, has worked in automated manufacturing plants both in Europe and America and brings a host of practical experience to the school.

Quick Facts

- Product Used: Mill, Lathe, Education Suite, Mastercam University

- Industry: Education

Project Details

- The Challenge: Develop a program for CAD/CAM and CNC Machining that would encourage students in the high school to advance toward a career in automated manufacturing, while helping technical college students gain new skills that will allow them to compete in today’s technologically advanced job market.

- The Solution: Mastercam and Mastercam University

- Benefits:

- Promotes several skill levels in class and at home

- Allows students to advance at their own pace

- Provides assistance for teachers

- Widely used in today’s manufacturing industry

At ATC, the high school students and the adult students in the Machining Technologies Program must complete the same comprehensive courses. The high school students start in their junior year three hours per day, attend six hours during the summer, and in their senior year attend three hours. The adults attend six hours per day for 14 months. ATC students also earn 6 or more credits applicable toward an A.S. degree in either Engineering Technology or Industrial Management at Broward Community College.

One of the aspects of ATC that attracted instructor Kevin Finan was the well-equipped machine shop that adjoined the classroom facilities, complete with several manual machine tools. Once on board, he began requisitioning the latest in automated equipment and received a Haas CNC machining center. He told the administration the machining center was “lonely,” and soon accepted delivery of a Haas CNC lathe, along with state-of-the-art CAD/CAM software.

“We use SOLIDWORKS® for the CAD portion of the program and we have Mastercam® for the CAM portion,” says Finan. “These are the two most prevalent systems in the marketplace and the ones our graduates will most likely encounter in the real world. We also purchased Mastercam University for the students. Each student now gets to use Mastercam University, which is specifically designed to teach Mastercam in an easy, step-by-step procedure through video tutorials right on their computer screen, in class and at home.”

Before getting into CNC machining, all students must first learn the basics of manual machining on the shop’s several manual mills and lathes, as well as rules of safety. Then, they are introduced to the writing of G and M codes for CNC programming. “I won’t ever introduce Mastercam to the student before he or she knows what G90 is or what G40 is,” says Finan, “and that they understand cutter compensation, that they’re not just pushing a button in Mastercam saying ‘compensate less’ without knowing what climb milling is.”

Once he feels the students are comfortable with the basics, he moves on to Mastercam. “What Mastercam does,” says Finan, “is create the tool paths from a student’s drawing, which is a wonderful and powerful program, but the student should really have an understanding what the codes are all about that the program is performing. So, once they learn G1, G2, G3, and so on, I’ll introduce them to Mastercam University.

“What Mastercam University will do to start is bring them up to the interface, such as what does this button do, what about that button, what is Design, what is Setting up Machine Parameters, and so on. Then, it teaches them how to create toolpaths for a series of practice parts from simple to those that are a little more complex. A teacher’s day is filled from beginning to end and if a problem arises in a CAD/CAM lesson, that problem can become a major headache without some sort of lifeline. A call to Mastercam is always answered and someone there will spend however long it takes to solve the problem and keep the class moving forward.”

Mastercam University provides modules for programming a dozen different parts, but Finan also encourages his students to create their own parts to keep their interest level high. “I had one young lady in the class who complained about a broken lock in the ladies’ bathroom,” he says. “She asked if she could fix it as a project. I told her ‘of course,’ and had her take a picture of it, along with pertinent dimensions. Using pieces of aluminum, she designed and machined a new part for the lock that worked perfectly. One student made a uniquely designed gearshift knob for his car and another produced a mounting device for stabilizing a camera. The students begin to see that everything in their homes, in stores, on television and in the world around them is manufactured and what they are learning comprise the basics for producing life’s tangibles.”

During the past few years, all of Mr. Finan’s high school seniors and most of his tech college adults have been awarded Mastercam University Certificates, attesting to their newly acquired skills in CAD/CAM programming. “While many of our graduates are going on to 2- and 4-year colleges, the rest are being recruited into well-paying jobs in local and regional industry,” says Finan. “These men and women are embarking on a pretty exciting career path, one that I have found even more exciting with each technological advancement in automated manufacturing.”

Customer Quote

“The students begin to see that everything in their homes, in stores, on television and in the world around them is manufactured and what they are learning comprise the basics for producing life’s tangibles.”

– Kevin Finan, Instructor, Machining Technologies Program, Atlantic Technical College and Technical High School

Mastercam Representative Quote

“A teacher’s day is filled from beginning to end and if a problem arises in a CAD/CAM lesson, that problem can become a major headache without some sort of lifeline. A call to Mastercam is always answered and someone there will spend however long it takes to solve the problem and keep the class moving forward.”

—Kevin Finan, Instructor, Machining Technologies Program, Atlantic Technical College and Technical High School