Attracting Future Tech Students Through Small-Scale CAD/CAM Demos

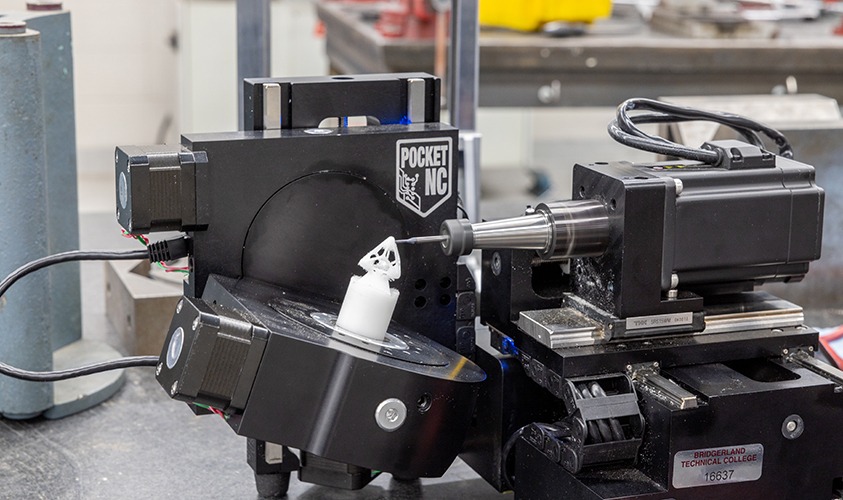

Bridgerland Technical College uses Mastercam to run Penta Machine’s 5-axis Pocket NC V2-10 mill at career fairs in its efforts to recruit students into its manufacturing program.

The Challenge

Demonstrating the power of CAD/CAM software and CNC machining within a small exhibit space.

The Solution

Mastercam, the most robust CAD/CAM software for machining applications.

Benefits

- Small footprint of the desktop mill and Mastercam software allow portability to exhibitions and career fairs.

- Students are drawn to Mastercam’s speed, ease of use, precision, and flexibility.

Project Details

We’ve heard it for decades: The United States has a skilled labor shortage. Most people in the manufacturing sector can attest to this shortage, specifically that of CNC programmers and machinists.

So, how are technical school administrators addressing the labor issue? A technical college in Logan, Utah is facing it head on by marketing its program to youths before they enter high school.With 40 students currently enrolled in its Machining Technology programand 20 high schoolers in its extension program, Bridgerland Technical College is preparing future programmers and machinists for Utah’s growing manufacturing sector.

One factor that doesn’t help alleviate the national labor shortage is the perception of manufacturing. Hirschi and his fellow instructors knew that addressing misconceptions would take more than focusing on high schoolers. Bridgerland faculty needed to reach younger students. Instructors started exhibiting at middle-school career fairs and hosting open houses. However, prior to 2022, the Bridgerland team was limited in what it could demonstrate at these fairs and off-site events.

“We couldn’t pick up a full-size Haas mill and lathe and take them into a high school or to a convention center—it’s not feasible. So, we would bring a laptop and the coolest parts we had, or parts that were donated by local machine shops,” said Hirschi.

For years, Bridgerland Tech relied on a simple exhibit set up: a laptop featuring a slide show and machining videos. Hirschi admits that the low-key marketing efforts lacked zeal, especially in comparison to other exhibits.

“There we were, in this really cool technical field, and we’ve got a table with some finished parts and a YouTube video,” he said. “One of the local machine shop owners actually called us out on it. He said, ‘This is really boring. You need something that’s going to interest these kids.’ If it’s not on TikTok or not a three-second sparkly, shiny video, the new generation of kids is not interested in it.”

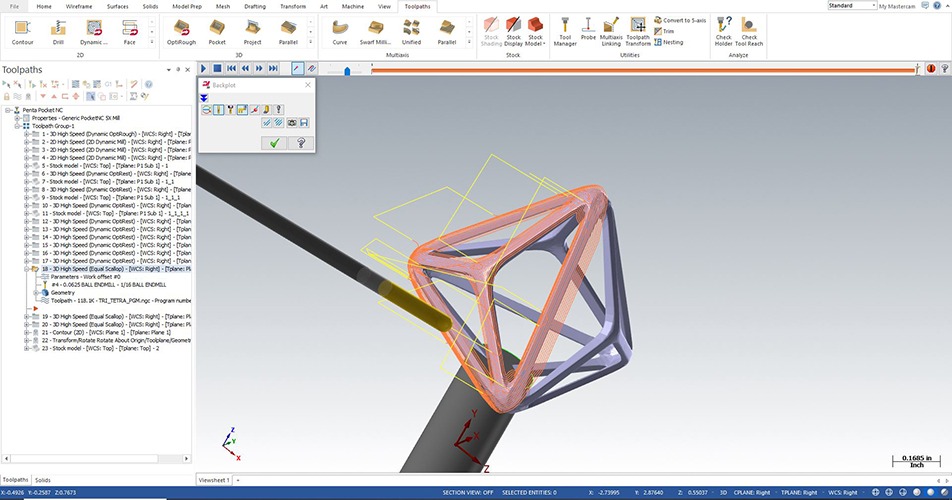

Hirschi and his team investigated ways to create a more impactful machining and marketing presence at events. They needed a hands-on way to demonstrate the speed and power of CNC machining, but on a portable, small scale. After some research, they purchased the 5-axis Pocket NC V2-10 from Penta Machine (Belgrade, Montana). It’s the first 5-axis CNC mill designed for desktop use. At Bridgerland, the Pocket NC mill is powered by Mastercam.

“Demonstrating Mastercam CAD/CAM on the Penta machine gets our foot in the door much better than running a slide show or a YouTube video would,” said Hirschi.

Bridgerland instructors show part examples and explain how the machine cuts. Next, they introduce the CAD/CAM software, explaining the design process, 3D models, and toolpaths. The Pocket NC and Mastercam areideal for helping people understand manufacturing. After Hirschi explains 3-axis machining, he demonstrates the 5-axis Pocket NC. So far, the response to Bridgerland’s eye-catching demos has been positive.

While the Penta Pocket NC is used in Bridgerland’s extension program to teach high schoolers the fundamentals of 5-axis machining, high school graduates entering the Machining Technology program use full-scale manual and CNC machines that they will likely encounter in the workplace. In the Machining Technology program, students experience hands-on learning plus coursework. Once they learn to operate manual lathes and mills, they move on to CNC machines, programming, and Mastercam.

“We’ve been teaching Mastercam for a long time,” said Hirschi. “Most of the shops here—I’d say 90 percent of them—use it. So, our students want to be on the machines and be hands-on learners.”

As for any software program, solid technical support is key in maintaining efficiency and staying current with technology. Hirschi and team count on Mastercam Reseller, MLC CAD Systems, Murray, Utah, for any needed assistance and guidance.

“We’re good friends with our MLC guys, Patrick Warren and Scott Lyndsay,” he said. “They support us any time we need something. When the 5-axis stuff was new to us, they helped set up the posts and simulation software so we didn’t crash the machines.”

Several large machine shops in Cache Valley are in close proximity to Bridgerland, so local employers like to hire from Bridgerland’s manufacturing program. The current job placement rate for a Bridgerland Technical College Machining Technology program graduate is 100 percent.

Quick Facts

- Product Used: Multiaxis

- Industry: Education

“We’ve been teaching Mastercam for a long time. Most of the shops here—I’d say 90 percent of them—use it. So, our students want to be on the machines and be hands-on learners.”

Trevor Hirschi, Instructor, Bridgerland Technical College, Logan, Utah