For Fast Prototyping, COBRA Golf Uses Advanced CAD/CAM Techniques

COBRA Golf’s R&D shop is dedicated to creating new golf equipment—mostly clubs—as well as tweaking and refining old equipment. To stay competitive, the shop must edit models quickly to make design adjustments and then get the parts off machines fast. To do it, they use Mastercam CAD/CAM software.

The Challenge

Editing the 3D models of custom golf equipment prototypes and then machining them quickly in order to meet customer demand.

The Solution

Mastercam, the most robust CAD/CAM software for machining applications.

Benefits

- Solid Model features that allow users to manipulate and edit 3D models without irrevocably changing the code

- Dynamic Motion technology which increases tool life while also minimizing cycle times

- Easily-accessible team of Mastercam Resellers who specialize in troubleshooting and advanced training

Project Details

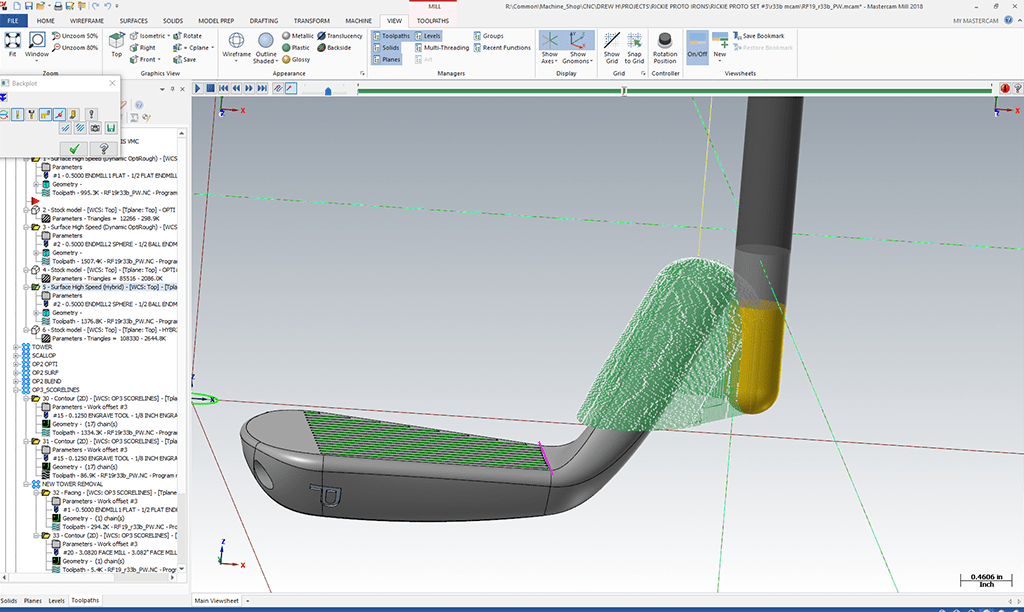

The COBRA Golf, Inc. R&D shop is where all the precision golf equipment for COBRA is designed and prototyped, two to three years ahead of large-scale production. Shop equipment includes two HAAS CNC mills (a 3-axis mill and a 3-axis plus a trunnion, converted into a 5-axis mill), a manual lathe, two Bridgeport mills, grinding machinery, and 3D printers. All CNC equipment is programmed with Mastercam CAD/CAM software.

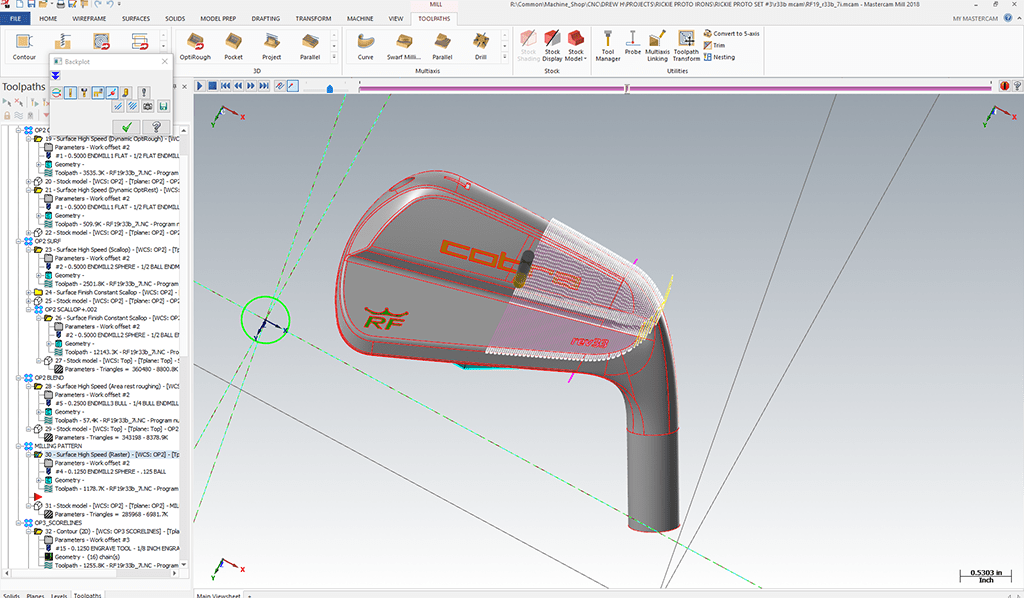

Because of strict weight specifications, the finishing phase for a custom golf club can recur several times before a part is ready for testing. The variety of part materials used by COBRA adds to the challenge of weight and tooling considerations. Machinists work with a wide range of materials including carbon steel, tungsten, copper, brass, and aluminum. They also use materials that mimic those used in the actual club,like 303 stainless steel, 17-4 stainless steel, 1018 carbon steel, and titanium.

“Because I can view the process through the software, I’m able to create code quickly and efficiently,” said Manny Garcia, CNC Programmer at COBRA. “Stock Modeling allows me to see what the machine is going to do before I do it and Tool Verification makes it easier to go from idea to actual cutting.

Dynamic Motion technology is another key feature of the CAD/CAM software. Compared to traditional cutting methods that use just the nose of the tool, Dynamic Motion uses the entire flute, yielding faster cuts, reduced machine vibration and wear, and extended tool life.

The cutting technology enables Garcia to create multiple toolpaths from one original toolpath. For example, for one application, Garcia starts with a high-speed OptiRough toolpath, which removes large amounts of material and creates a fully roughed part in less time than with traditional machining methods.

Next, dry surfaces and fixtures are laid out and Garcia simply copies and pastes that specific toolpath instead of selecting others within the menu. This programming feature speeds up the process and reduces machine start-up time. Once machining begins, Mastercam’s Solid Model Editing helps optimize workflow.

“With Mastercam, I don’t have to go back to an engineer to have him redesign or give me new specs; I can just tweak the 3D model in my software,” Garcia said. “I have a Push/Pull function, a Move function, and Modify feature, all within Model Prep. These features simplify the editing process andeliminate additional programming time.”

Garcia has been using Mastercam for two years, and says he is always learning about new capabilities. He credits MLC CAD Systems (San Diego, CA), COBRA’s Mastercam Reseller, with providing helpful product training in addition to great ongoing support.

Thanks to the capabilities of CAD/CAM software, programming and milling challenges of all sizes and types abound in COBRA R&D Machine Shop.

Quick Facts

- Product Used: Mastercam Mill

- Industry: Job Shop, Sports Equipment, Golf Equipment

“Mastercam allows me to take these really complex shapes and give the machine the exact instructions I want. It makes it all seamless and efficient, which is important because we have to be quick. The faster the shop can make the club, the faster engineering can complete a test, get an answer, then go back and either make material or construction changes or move on to the next phase of design or development.”

Manny Garcia, CNC Programmer and Machinist, COBRA Golf, Carlsbad, CA