5-Axis Solutions Open New Doors for McAfee Tool & Die

McAfee Tool & Die is known for taking on unique jobs, and the reason for that is their dedication to constant progress. When 5-axis milling started to become more popular, McAfee immediately looked for ways to maximize the benefits of the new technology, choosing an investment in Mastercam for best results.

Quick Facts:

Product Used: Mill, Mill-Turn, Lathe, Multiaxis

Industry: Tool & Die, Job Shop, Automotive, Energy

Project Details:

- The Challenge: Evolve shop capabilities to stay ahead of client needs with advanced machining strategies like 5-axis milling.

- The Solution: Evolve shop capabilities to stay ahead of client needs with advanced machining strategies like 5-axis milling.

- Benefits:

- Easy to learn and use.

- Advanced 5-axis solutions enable shops to produce highly complex parts with minimal setups.

- A vast network of local Mastercam Representatives who are ready to lend their expert advice.

McAfee Tool and Die has been providing tool and die stampings, reverse engineering, concept design, prototyping, and permanent tooling services for Northeast Ohio since 1977. In more than forty years of operation, McAfee Tool & Die has expanded their customer base across many other states and foreign countries. Being certified to ISO 9001:2015, as well as for aerospace with AS 9100:2016 (Rev. D), rounds out this company’s ability to serve the manufacturing industry.

Owner Gary McAfee appreciates the value of running a shop that is versatile and can take on a wide variety of jobs.

“When it comes to software, we wanted something that’s functional for everything we do, and we do a lot of different things. It’s important that this software is flexible enough,” said plant manager Joseph Lysiak. That’s why his team chose Mastercam as the company’s CAD/CAM solution.

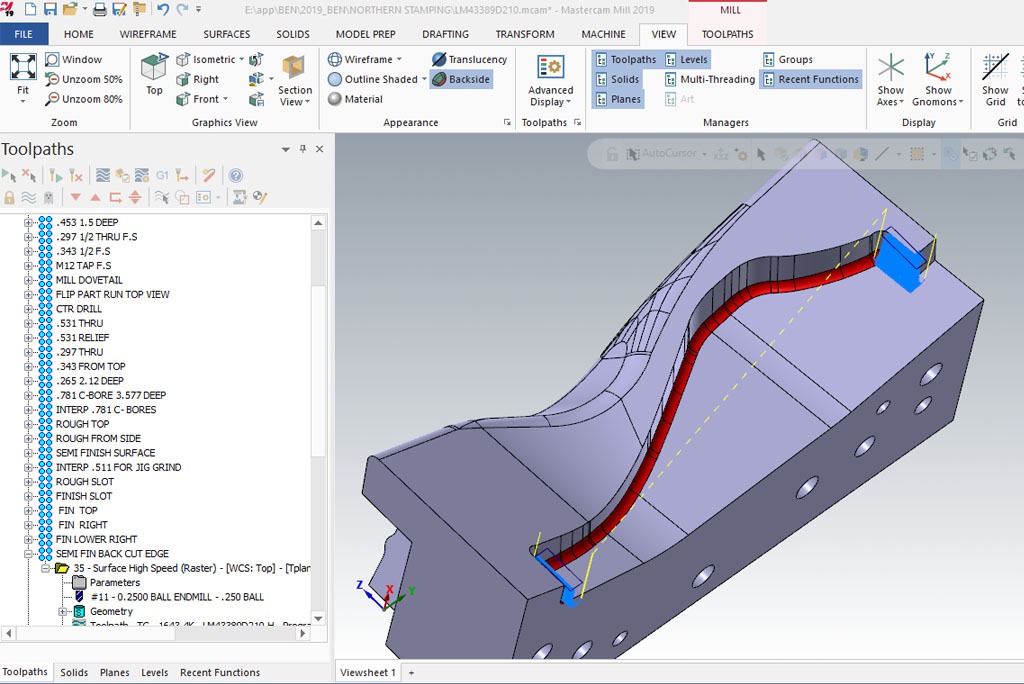

John Stiles, a senior programmer, reached out to Mastercam Representative, FASTech, Inc. to ask Kevin Richardson, sales manager, and technical expert, about the specific features within the software. Richardson personally visited the McAfee Tool & Die shop with technical expert Scott Harding to give a demonstration. During his visit, Richardson programmed a real part for one of McAfee Tool & Die’s orders, explaining each step to Stiles and programmer Ben Ohler. “We got a time pressing job completed and were able to see firsthand the high level of support,” said Ohler.

While there, Harding explained the training, support, and troubleshooting help McAfee Tool & Die could expect from FASTech. McAfee knew that a transition to a new CAD/CAM software might be expensive at first, but he quickly realized that FASTech’s support contract was the best deal on the market. McAfee Tool & Die made the switch to Mastercam and hasn’t looked back since.

Stiles explained, “They included translators, post processors, and support in the base cost. With some software companies, many things are extras that add to your base cost as well as the annual cost of your support contract. With the overall time and support we get from them, it means everything when you come down to it.”

The McAfee Tool & Die team relies on Harding’s continued support as new technologies become available. “Once in a while, we’ll run into something that makes us call support. They get right on, and we share screens so they can walk us through it,” Stiles said. “It’s most valuable to have them when we need to learn something new, though.” Over about four days via on-site training, Harding walked the McAfee Tool & Die programmers through the intricacies and advantages of 5-axis milling.

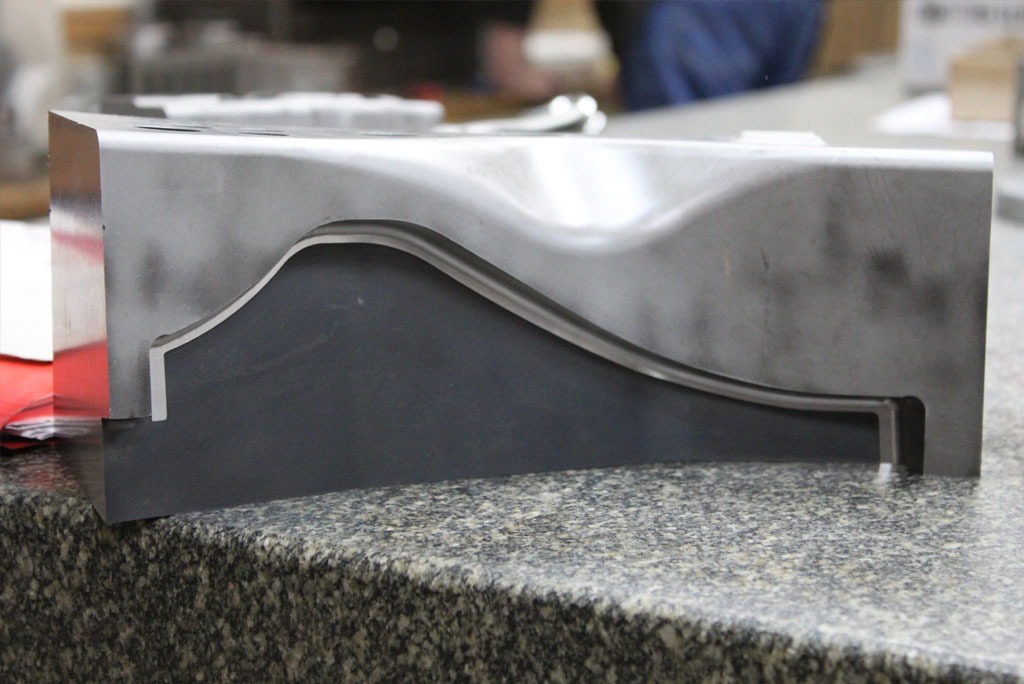

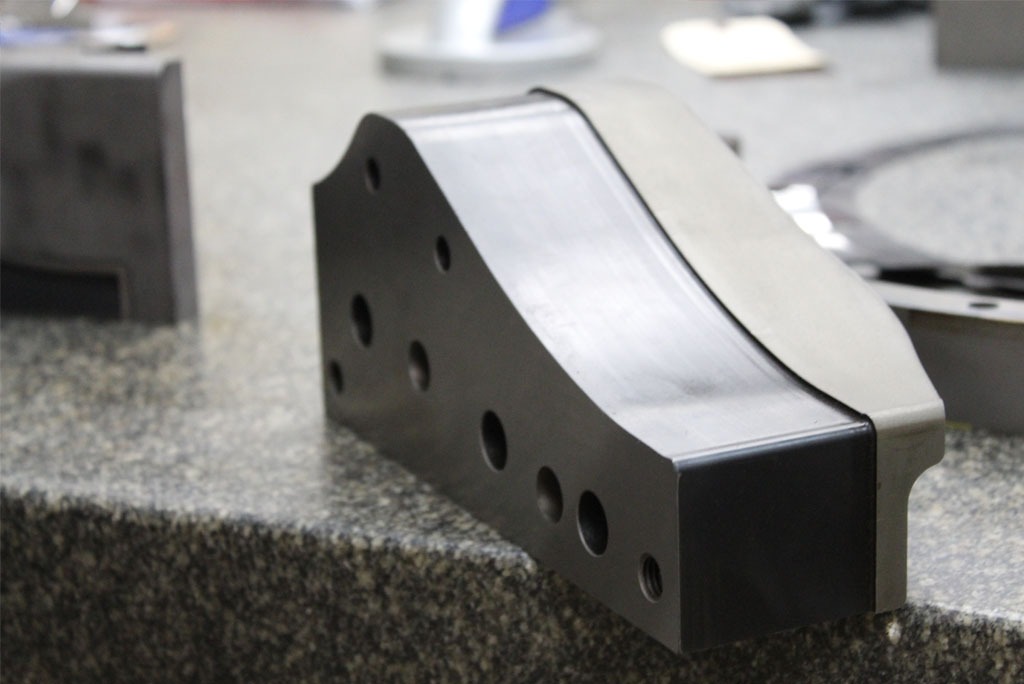

5-axis milling with Mastercam has changed the way McAfee Tool & Die manufactures parts by eliminating setups and streamlining the entire machining process. Now, Lysiak is unconcerned about damaging his stock material, even though machining with 5-axis is inherently faster.

“We have parts with tolerances of less than ½ thousandths, but we don’t have to worry. We can have anyone put it in, push a button, and go. He won’t have to take it off and put it back in again and again, either. Time is money,” Lysiak shared. With McAfee Tool & Die’s expanded capabilities, his only concern now is keeping up with increased orders.

While updating equipment and software on a regular basis creates some challenges, the McAfee Tool & Die team agrees that it creates many more opportunities for expanding business. “The improvement in programming and the new technology that the software is always evolving helps us stay ahead of the curve and meet customer demand,” said Lysiak. “When I talk about bringing in more work, the guys in programming just say, ’Bring it on.’”

McAfee Tool & Die continues to push boundaries and to learn new ways to approach projects. It not only makes the company more productive and competitive, it opens the door for new customers and expanded opportunities.

Customer Quote

“The improvement in programming and the new technology that the software is always evolving helps us stay ahead of the curve and meet customer demand.”

—Joseph Lysiak, Plant Manager, McAfee Tool & Die, Uniontown, Ohio

Mastercam Representative Quote

“They included translators, post processors, and support in the base cost. With some software companies, many things are extras that add to your base cost as well as the annual cost of your support contract. With the overall time and support we get from them, it means everything when you come down to it.”

—John Stiles, Senior Programmer, McAfee Tool & Die, Uniontown, Ohio