Napoleon Machine Forged in Family

At Napoleon Machine, the significance of hard work is at the center of its core values. In fact, the tag line in its jobseeker video on the company’s career web page warns, “Lazy folks need not apply.” As businesses were struggling across the northeastern and midwestern United States, Napoleon Machine was establishing itself as a major player in the aerospace, automotive, and U.S. Department of Defense (DOD) contracts in its namesake Ohio city, 44 miles southwest of Toledo.

The Challenge

Precision machining under strict deadlines and tolerances—especially on U.S. Department of Defense (DOD) projects like the M1-A2C Abrams tank—demand versatility and scalable tools for design and production.

The Solution

Mastercam, the most robust CAD/CAM software for machining applications.

Benefits

- Dynamic Motion enables faster feeds and speeds.

- Scalable tool libraries save valuable man hours.

- 5-axis machining control doubles spindle RPM speeds.

Project Details

Progressive manufacturing technology is the core of business for Napoleon Machine. Since 2012, it has invested some $6 million on welding and machining technology including modular fixturing systems, magnetic work-holding, shrink-fit tools, automated probing, 5-axis machining, and the latest in CNC programming software—Mastercam.

Napoleon Machine’s modular sub-tables and custom modular fixtures are keys to meeting DOD contract demands. The M1 tank job repeats 20 times per month on average, and modular tools are essential to ensure that all repeat parts for the main battle tank for the U.S. Army and Marine Corps is set up the same way each and every time.

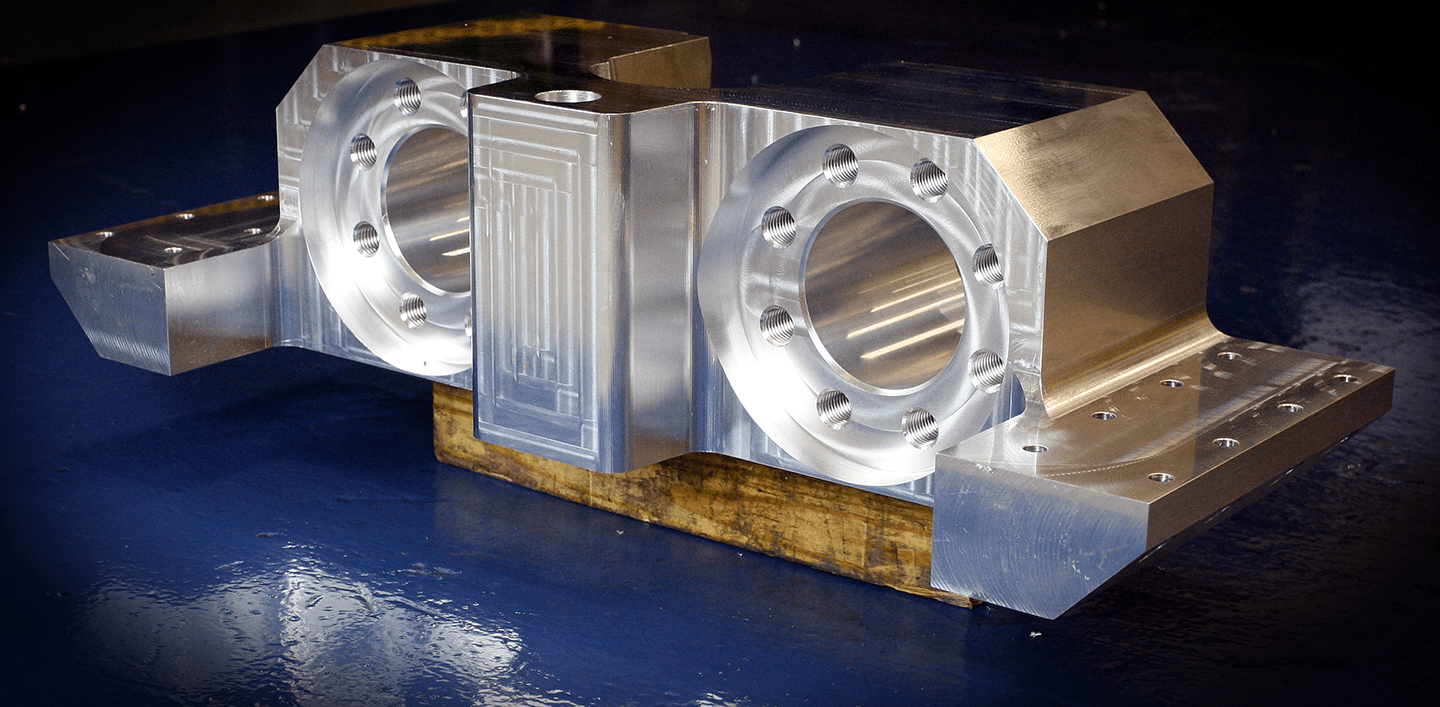

Each step in the process is inspected thoroughly, with zero margin for error. Tight tolerance CNC machining was required, and Napoleon Machine produced the mainframe, column, base, gearbox, and linear guide rail surfaces for a military missile project.

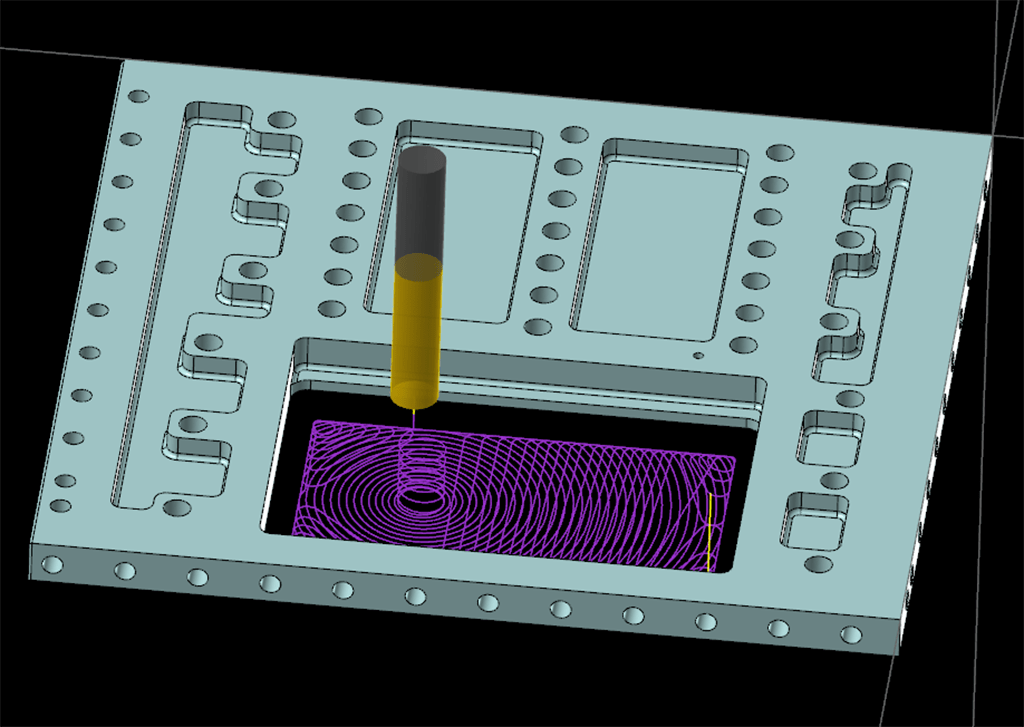

Each machine has its own comprehensive Mastercam tool library, which saves valuable man hours. By importing tool libraries directly into the CAD/CAM software, the machinist does not need to search for tools in a catalog and manually build them in Mastercam.

For every machine, Napoleon has a table of all its modular fixturing components which are saved as Mastercam files.

Additional software features like Dynamic Motion technology help Napoleon machinists tackle most any challenge. Aluminum stock coupled with Dynamic Motion enables faster feeds and speeds—especially with a new 5-axis machine coming online.

Napoleon machines aluminum at 350 inches per minute, which will change with a new 5-axis machine because its RPMs are much higher. Currently, the company’s fastest machine has a 10,000 RPM spindle; the new one will have a 20,000 RPM spindle.

In addition, the CAD/CAM software eliminates machine idle time and ramps up output through offline programming.

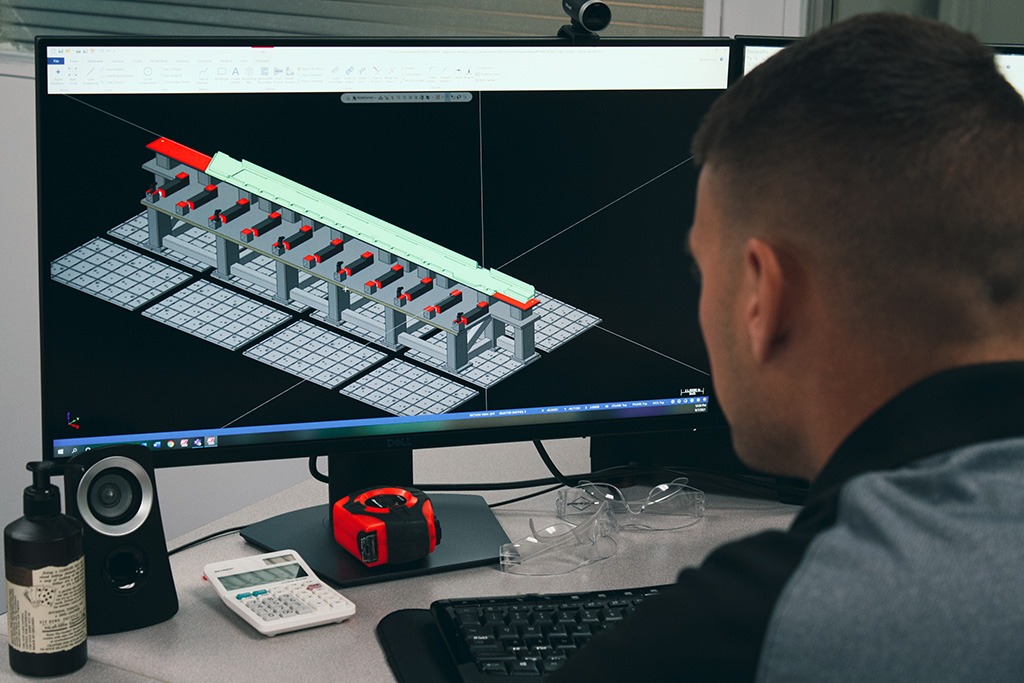

Neil Hanenkratt, CNC Programmer at Napoleon says the benefits they see from Mastercam can all be summed up with one word.

“Efficiency. I can make a blueprint, draw a part, program parts, edit models — you name it, you can do it. It’s pretty powerful software. You don’t have to hand-calculate everything anymore. The software really took efficiency to a whole new level.”

Quick Facts

- Product Used: Mastercam Mill, Multiaxis, Dynamic Motion

- Industry: Aerospace & Defense, Agriculture, Heavy Equipment, Food &Beverage, Mining, Nuclear Power, Oil &Gas

“Mastercam is a one-stop-shop. You can do almost anything in that software. I can make a blueprint, draw a part, program parts, edit models—you name it, you can do it…It really took efficiency to a whole new level.”

Neil Hanenkratt, CNC Programmer, Napoleon Machine, Napoleon, OH