Mastercam 2025 is the latest edition of the world’s leading CAD/CAM software, intentionally upgraded to make programming fast and easy.

It prioritizes streamlining workflow so that the entire machining process – from design to QC – is as efficient as possible. Explore these tips and features to help you maximize the benefits of Mastercam 2025!

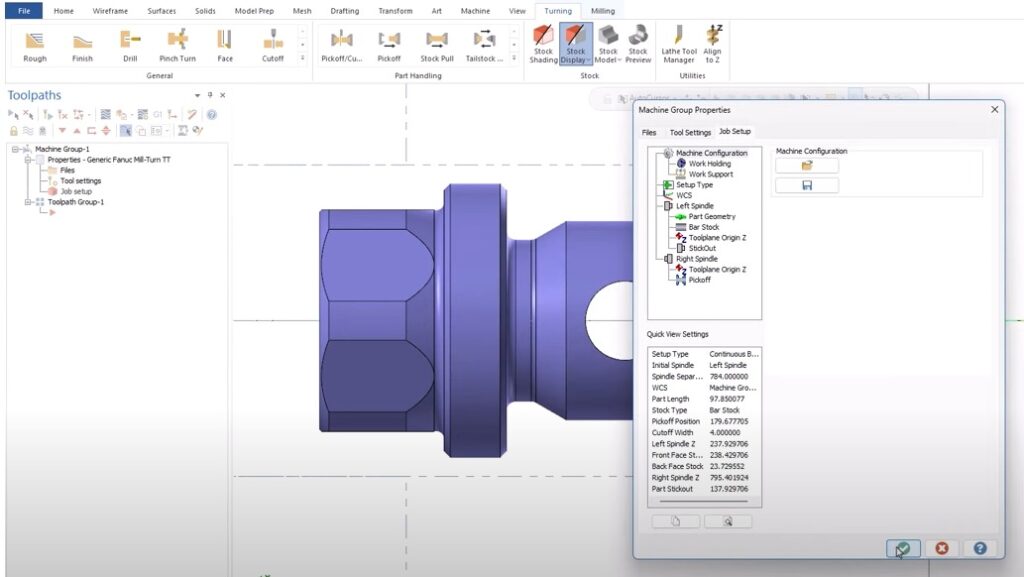

1. Saving and Loading Machine Configurations

In Mastercam 2025, Mill-Turn users now have the capability to save unique machine configurations into individual files, streamlining setup for new projects. This advancement is super useful when processing families of parts or when you have tools and fixturing that rarely leave the machine.

Your configuration file can be stored anywhere on your workstation! Power users can store the configuration right in the Mill-Turn’s respective .machine file under the “Machine Configuration” files node.

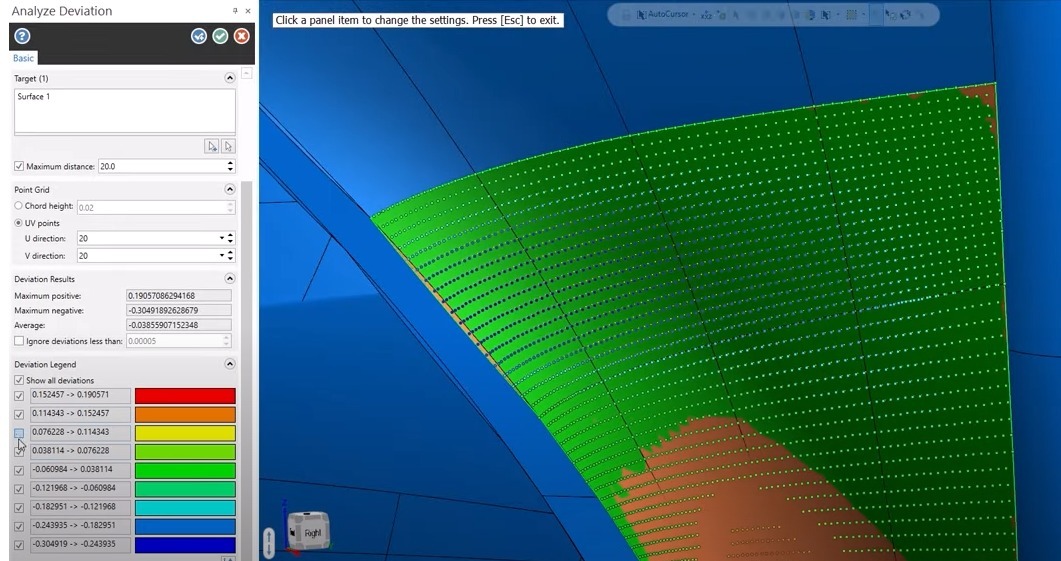

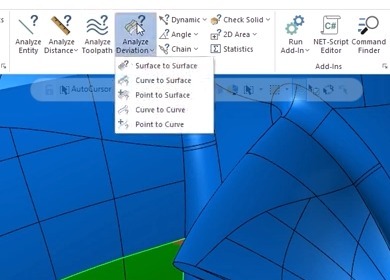

2. Analyze Deviation

Mastercam 2025 introduces a new suite of tools designed to help analyze your CAD models. The new Analyze Deviation function includes an assortment of tools to help measure distances between multiple entities.

Whether you need to measure distances between surfaces, curves, or points –this function can help identify distances between any combination of these entities and display the results in an easy-to-read graphical interface.

The Analyze Deviation function is extremely versatile and can help you analyze your models, so you know exactly what you’re working with.

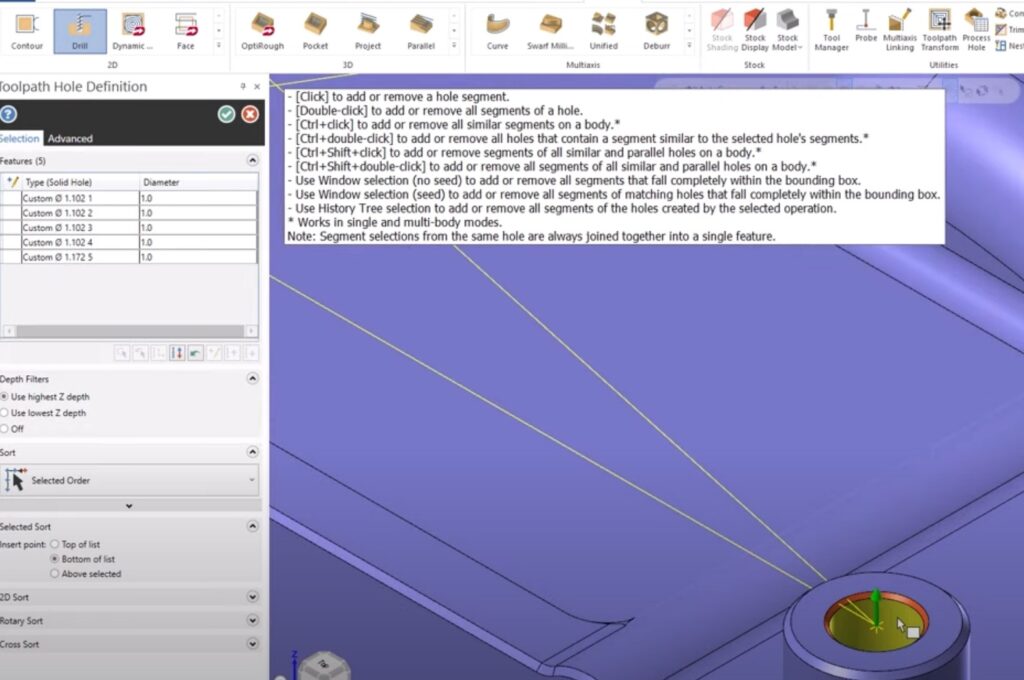

3. Solid Hole Selection

In Mastercam 2025, Solid Hole selection capabilities were expanded to provide users with a much more efficient workflow. You can now save a lot of time by not requiring the use of the Find Hole function before making Solid Hole selections.

Mastercam 2025 can now select hole shapes directly from the solid body without model history. Even parts imported directly from other CAD formats can have the hole features directly selected. We have also added more filters to select multiple hole features more intelligently.

These new Solid Hole selection changes greatly improve Mastercam’s hole making workflow, increasing efficiency and gives users more control over programming hole features.

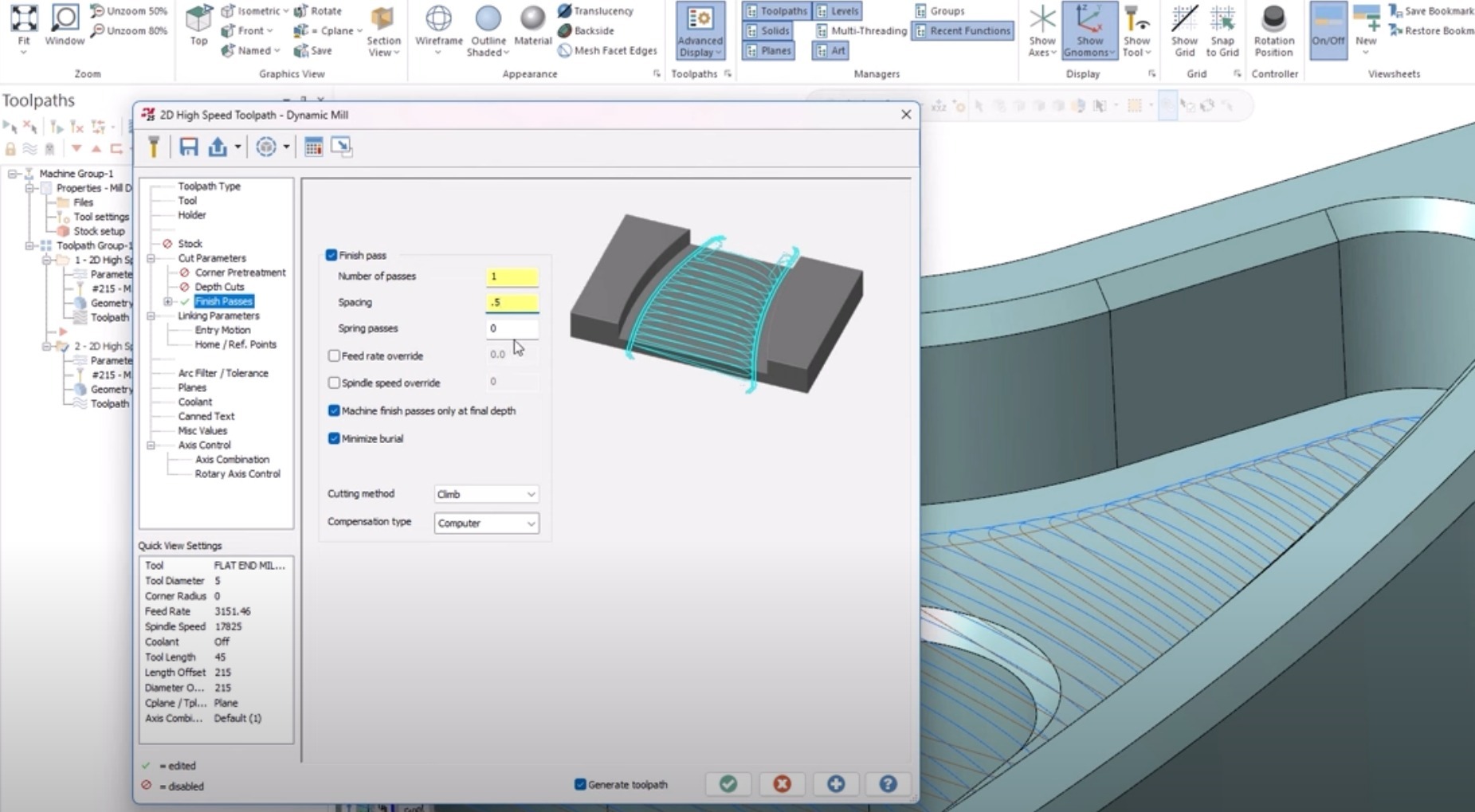

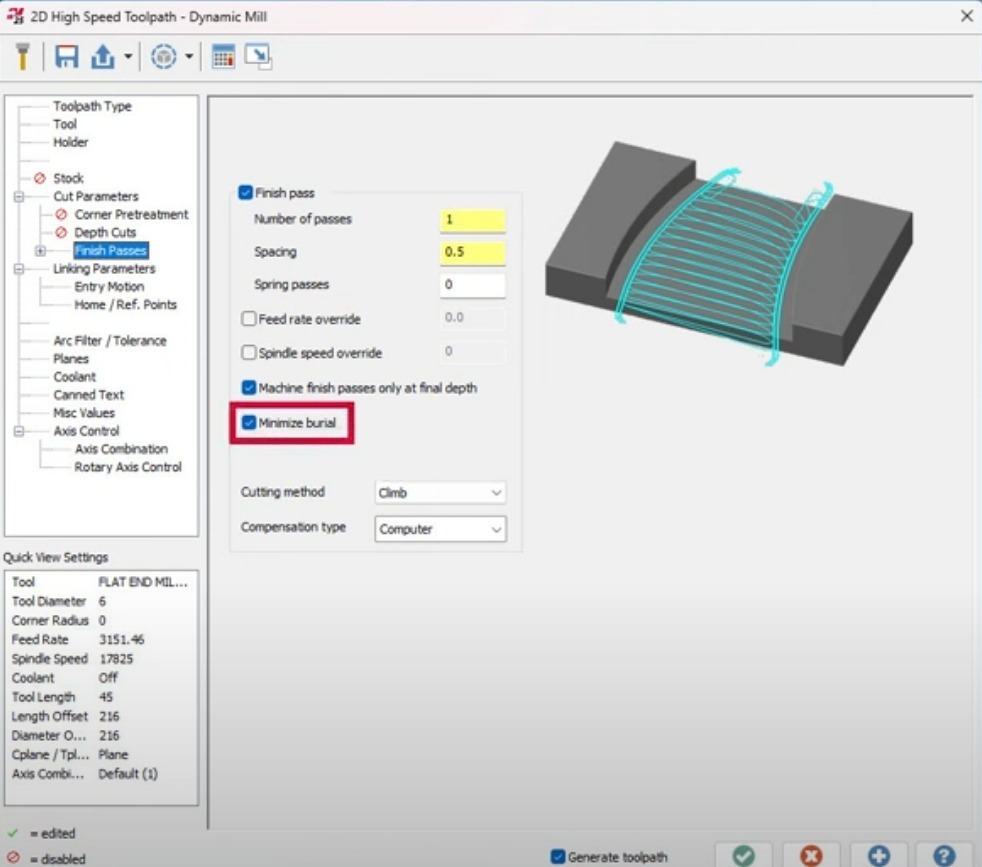

4. Finishing Passes for Dynamic Toolpath

Mastercam’s Dynamic Toolpath functionality has been a game changer in the world of manufacturing. It reduces cycle times, increases tool life, and minimizes wear and tear on your machines.

In Mastercam 2025, we have continued to enhance this toolpath motion with the addition of finish passes. We have also added a Minimize Burial option to keep your tool from over-engaging in both 2D Dynamic Mill and Area Mill toolpaths. This enhancement will streamline your programming process when working with these popular toolpaths.

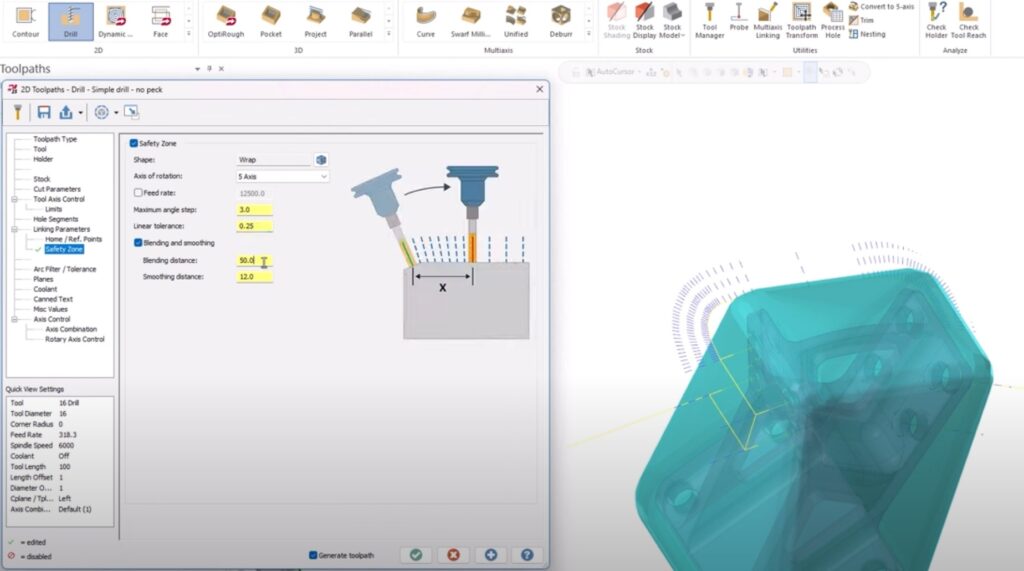

5. Improvements to Multiaxis Safety Zone

Safety Zone for hole making has been overhauled in Mastercam 2025 with a new algorithm for improved transition movement. This enhancement has allowed us to introduce new parameters, so users have more control over transition motion.

In Mastercam 2025, Safety Zone will now use a mesh in the background for all the defined shapes in the Safety Zone panel for the linking calculation. The ability to edit the vectors with respect to the Safety Zone shape results in better tool-angle motion for linking moves.

These new parameters in the Safety Zone page include a linear tolerance value, blending distance, and smoothing distance values.

Learn More

If you’re serious about streamlining the workflow in your shop, your local Mastercam Channel Partner is one of your most valuable assets to talk to about upgrading to Mastercam 2025. Reach out to yours here!