The Nike of Samothrace project is a stunning example of how modern CNC machining and manufacturing combines machine art and technology. As we celebrate Manufacturing Day on October 4th this year, this celebration not only highlights the importance of collaborations among various professionals in the manufacturing sector but showcases how they come together to create beautiful works like this iconic statue replica.

Join us as we explore the intricate machining and programming processes behind the Nike of Samothrace project and shine a spotlight on the diverse career opportunities that contribute to such remarkable projects.

Project Overview

The Nike of Samothrace, aka ‘Winged Victory’, is an iconic statue located in the Louvre Museum in Paris, France. Known for its dynamic pose and artisanship, this ancient masterpiece was originally sculpted around 190 BC. Mastercam’s goal in creating a replica of this statue was not only educational but artistic, providing a platform for innovation in modern manufacturing and hoping to illustrate the robust capabilities of the Mastercam software.

This ambitious project was made possible through the collaboration of various teams, including Mastercam’s Partnership, Sales Engineer, and Marketing departments, as well as key industry partners such as YASDA Precision, Mitsubishi Materials, Methods Machine Tools, and 5th Axis – each contributing their expertise to bring this masterful vision to life.

Manufacturing Processes

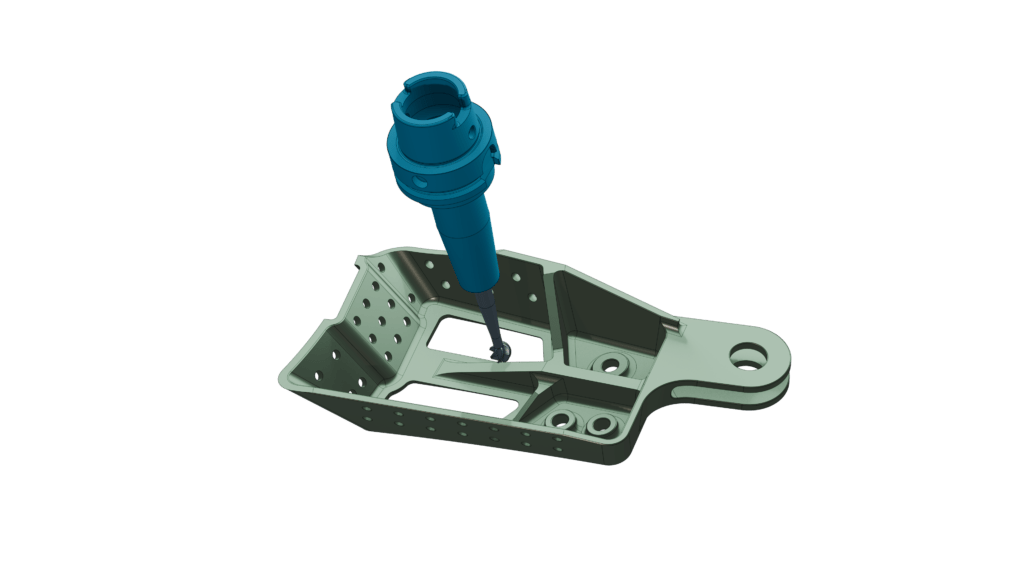

The machining and manufacturing processes used in creating the Nike of Samothrace statue highlight the power of Mastercam, modern technology, and the skilled professionals who driver innovation in the field. Mastercam software played a crucial role, offering advanced features and products that allowed for precise and intricate fabrication. For a closer look at the key features and tools used in creating the Nike of Samothrace, view A Closer Look: Creating the Nike of Samothrace Statue blog.

How Manufacturing Careers Come Together

The creation of the Nike of Samothrace statue exemplifies how diverse career paths in manufacturing come together to turn concepts into reality. Meetings between several departments, like Mastercam’s Partnerships, Sales Engineering, and Marketing teams, were crucial for refining and detailing the project, demonstrating how internal as well as external, collaboration is a vital part of manufacturing projects.

We reached out to key team members involved in the making of the Nike project, to learn more about their roles.

Interview with Dave Miller – Manager, Sales Engineering – Key Accounts

What factors did you consider when selecting partners for the Nike of Samothrace project, and how did you evaluate their capabilities?

When approaching a high-profile project like the Nike of Samothrace, one has to consider some major factors. Some are based on the project like quality of the machine or their specialty/position in the industry. This is important because you wouldn’t want to do micro machining on a machine that is meant for fracking blocks. Other factors that one might not consider right off the bat would be the quality of partnership, marketing, as well as the quality of their applications team. These factors, along with many others, contribute to the recipe for success in these high-profile demo projects.

Can you share a memorable moment from the collaboration process that highlighted the importance of teamwork in this project?

A valuable lesson to learn as early as possible is that you don’t know everything and that there are 17 different ways to accomplish every part or feature. Whether you are the one designing the part, spec’ing out the fixture/tools, programming, running the machine or even just passing by the machine while it’s running, everyone has very valuable opinions and input. This input could be a slightly different feed rate to reduce chatter or a different machine precision mode or even a completely different tool to be used. All in which help make these projects come together. Everyone involved in the Nike project added different inputs on technologies to get the best result.

What skills do you believe are essential for someone looking to build a career in partnership management within the manufacturing industry?

Partnership Management requires a well-rounded individual. On one hand you need to be personable and build rapport with your Partners. While doing this, we still have a sales mindset, because we are always selling. The software, the company, the partnership, and even ourselves. On the other hand, you need to also be technically advanced in manufacturing, programming, and machining.

Interview with Chad Chmura, Sales Engineer

What were the biggest challenges you faced while programming the Nike of Samothrace models in Mastercam, and how did you overcome them?

Our aim for this project was perfection. We sought to achieve the highest level of detail and the finest surface finish possible. As with all our Signature Part projects, it was crucial to understand the machine parameters and point density that the machine required to operate at its best. The Yasda PX30i – which machined this project – blurs the line between a CNC machine and a scientific instrument. Understanding its requirements was a significant challenge, but one we successfully overcame.

Can you describe a specific feature of Mastercam that was particularly beneficial in achieving the intricate details of the statue?

This project wouldn’t have been possible without the Multiaxis Unified toolpath, though I believe it wasn’t the most crucial Mastercam feature. The key was actually an option within our 3D HST Waterline toolpath. The Waterline toolpath is a finishing toolpath that steps the tool down a constant Z distance incrementally between each cut. Some of the trenches in Nike’s robes required an extreme tool reach, beyond what the tool could achieve with default settings. The little-known “Tool Assembly Contact” feature enabled the finishing tool to reach the full depth of every pocket, allowing us to achieve perfect detail.

What advice would you give to someone interested in pursuing a career as a sales engineer in the manufacturing sector?

Following your passions is crucial. Manufacturing is a field that intersects with many of your interests. For me, it was cars. I love working on cars and creating things. Manufacturing allowed me to make custom parts for my own vehicles. Over time, I discovered many other aspects of the industry that I enjoyed. Becoming a Sales Engineer was a natural progression, combining technical knowledge with the opportunity to interact and share experiences with others.

Everything you encounter daily had to be manufactured somewhere. Find out how something you enjoy was made, and use that as a stepping stone to a potential career.

Interview with Courtney Riley, Marketing Brand Manager

What strategies did you implement to effectively showcase the Nike of Samothrace project to the public and industry stakeholders?

Collaboration with our internal team and partnerships to understand the advance machining that went into creating this part and then working through how to best showcase those features through video, content, and imagery.

How did you measure the success of the marketing campaign surrounding this project, and what metrics were most important?

There are many metrics we consider measuring the success of a marketing campaign. For me, engagement is the most important. Engagement shows that the audience is interacting with our posts through likes, comments, or reshares, which helps the team continue to produce engaging content.

What insights can you share about career opportunities in marketing within the manufacturing sector, and what skills are most in demand?

Marketing within the manufacturing sector typically allows marketers to focus on a single brand. Within this field, individuals collaborate across the business, enabling them to gain a comprehensive understanding of the entire operation. Essential skills for success in marketing include attention to detail, the ability to work in a fast-paced environment, and a commitment to continually growing one’s skill set.

Get Involved

The creation of the Nike of Samothrace statue is an inspiring example of the diverse career paths available in the manufacturing sector, particularly those related to CAD/CAM, CNC, machine art, and technology. From the machinists and programmers to the teams making the partnership connections and driving marketing initiatives, there are a wide range of opportunities for involvement in the manufacturing industry. At Mastercam, we encourage readers to explore these opportunities, where innovation and creativity unite.

For more information on careers in manufacturing, visit the official MFG Day website.

Want More Information?

Curious to dive deeper into the programming and creation process of the Nike of Samothrace statue?

In celebration of MFG Day, we invite you to check out our Nike of Samothrace content and discover the deeper aspects of manufacturing through our resources. Explore our comprehensive 14-video playlist on YouTube here.

For Mastercam users, access the Nike of Samothrace files on our Tech Exchange.

Be sure to check back next Friday for the next installment of our “How It’s Made” series as we continue celebrating Manufacturing Month!