In the evolving world of manufacturing, the role of education is more critical than ever. At Mastercam, we are dedicated to addressing the industry’s challenges by equipping the next generation with the skills and knowledge they need to succeed. We were fortunate enough to speak with Clint Smith, Sr. Education Market Specialist at Mastercam, whose role presents the unique opportunity to work closely with educators, students, and industry partners to bridge the gap between education and industry demands.

A Day in the Life of a Sr. Education Market Specialist at Mastercam

At Mastercam, our mission is to create software and services that solve the world’s manufacturing challenges. As a Sr. Education Market Specialist, I view my work through this mission’s lens. My role involves collaborating with customers and Channel Partners to address one of the largest challenges in manufacturing: the skilled labor shortage, both in the United States and globally.

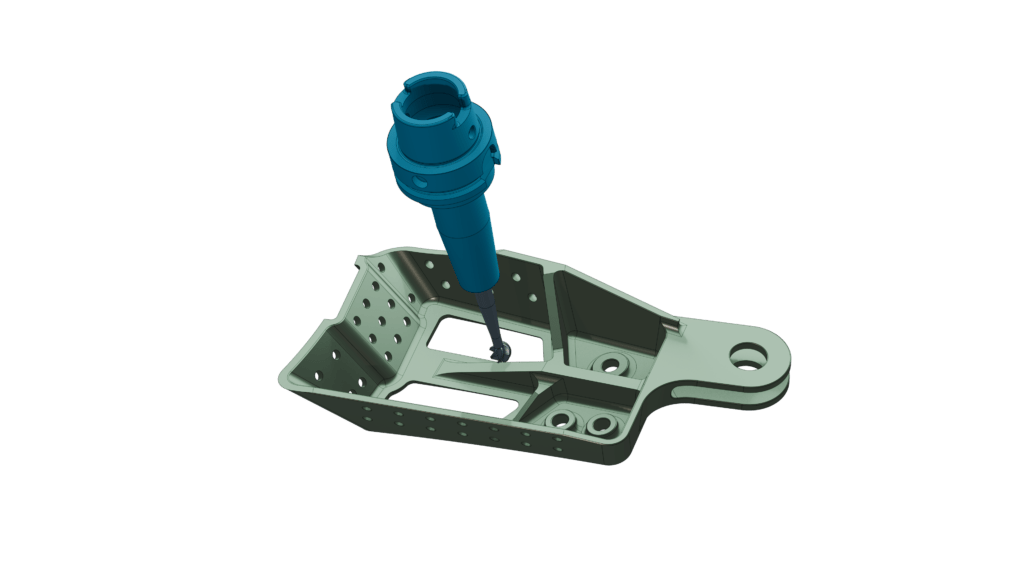

Mastercam is a leader in the industrial CAD/CAM market, and we strive to ensure that our software is taught at educational institutions worldwide. This exposure and training prepare students for the industry demands they will face. I have the privilege of working alongside educators to assist with implementing Mastercam in classrooms, ensuring students are well-prepared for their future careers.

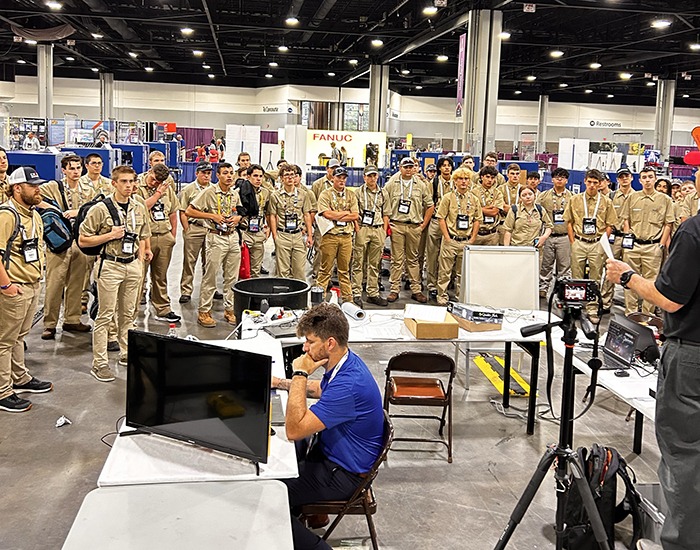

I also work closely with Mastercam’s Education Partners, including prominent workforce development organizations like WorldSkills, EuroSkills, Project MFG, and SkillsUSA. These organizations highlight the importance of skilled trades through student competitions, and we ensure Mastercam is the software of choice by providing software, support, and learning resources.

One of my key responsibilities is representing Mastercam as the Technical Committee co-chair for the CNC competitions at SkillsUSA. The Tech Committee, comprising individuals from leading manufacturing companies, creates resources and sets the direction for CNC competitions at state and national levels.

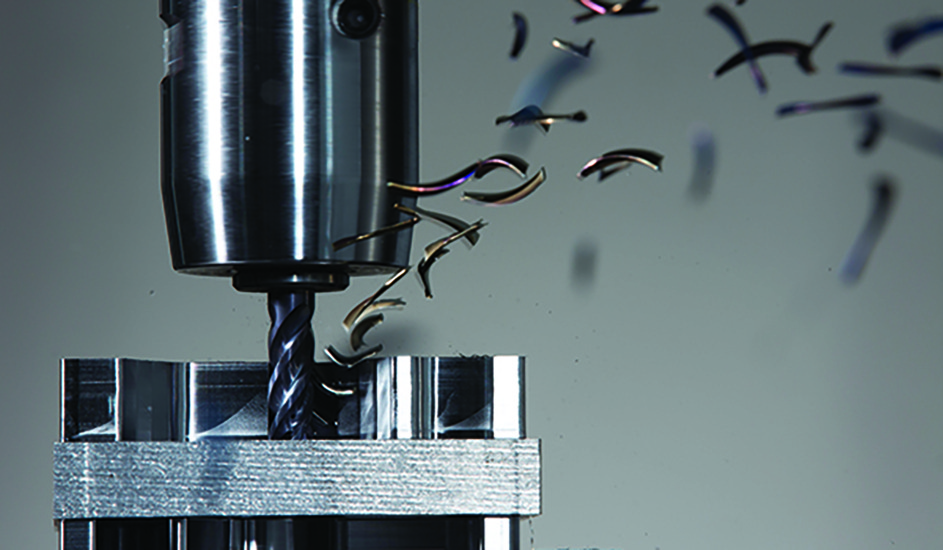

Over the past five years, manufacturing education has rapidly adopted advanced technologies like multiaxis machining, thanks to competitions such as SkillsUSA and Project MFG. Many high schools now use the Mastercam Educational Suite’s powerful Multiaxis toolpaths, moving from manual G-code to CAD/CAM programming, and better matching industry requirements.

Insights on SkillsUSA and Clint’s Role as Co-Chair

Skills competitions have become a passion for me during my time at Mastercam. Each competition reminds me that our future is in capable and talented hands. I am consistently impressed by the skill and dedication of the students. The current generation embraces technology and learns it rapidly, with high school students successfully programming and machining complex 5-axis components under pressure.

At Mastercam, we are dedicated to shaping the future of manufacturing. When the opportunity to co-chair the SkillsUSA Technical Committee presented itself, I accepted with enthusiasm. It is a privilege to support educators and students who represent the future of our workforce.

My journey began as a student in the precision machining program at Vincennes University, where I was first exposed to Mastercam. Unlike many of my classmates, I had no machining experience when I started college. With the support of my professors and classmates, I realized my potential in the trade. This experience shaped my perspective, and now, nearly twenty years later, I feel responsible for ensuring students have the support and resources they need to succeed.

Looking Ahead: The Future of Technical Education

Manufacturing is quickly advancing with the rise of automation and artificial intelligence. Educators face the challenge of keeping up with technological advances while maintaining a focus on programming, machining, and metrology fundamentals. Fortunately, we have abundant learning resources and eager manufacturers willing to partner with educational institutions.

I believe we will continue to see significant investments from state and federal governments to ensure a strong manufacturing workforce. This will improve infrastructure, equipment, and technology in manufacturing programs worldwide. We will see more world-class facilities like those at Southwestern Illinois College and Vincennes University, which excite students with their modern, high-tech environments.

The most critical skills include learning the fundamentals of CNC machining and programming. Understanding the “why” behind programming is vital for effective use of software like Mastercam. Creative thinking about machine setups and machining strategies, deep diving into feeds and speeds, and leveraging the power of Dynamic Motion in Mastercam can enhance efficiency. A deep understanding of metrology and GD&T is also crucial. Most importantly, having a good attitude, teamwork, and a willingness to learn and adapt are invaluable skills.

The Technical Committee continues to design projects for the SkillsUSA CNC competitions. We have transitioned the competitions from longhand G-code programming to CAD/CAM programming and verification with Mastercam and its sister company, Vericut, both of which are owned by Sandvik. We aim to keep evolving the competition to match our ever-changing industry and push the boundaries of what’s possible for students.

Pioneering the Future of Manufacturing Through Technology

The future of manufacturing relies heavily on the education and training of the next generation. At Mastercam, we are committed to shaping this future by providing the tools, resources, and support needed to prepare students for successful careers in manufacturing. Through partnerships with educational institutions and organizations like SkillsUSA, we are helping to bridge the gap between education and industry, ensuring that students are equipped with the skills they need to thrive. As we look ahead, we remain dedicated to evolving our programs and supporting the continuous growth and development of the manufacturing workforce. View the programs Mastercam is currently involved in.