Mastercam Deburr is designed to reduce costs and programming times while enhancing productivity by eliminating the need for hand deburring. This not only improves the quality of your finished parts but also increases the overall efficiency of your shop!

Do you frequently use the contour toolpath in Mastercam to Deburr? You may have had to manually trim the contour in the lead in/lead out page to avoid adjacent part surfaces, but this is now a thing of the past with Mastercam Deburr.

What Makes Mastercam Deburr Unique?

If you haven’t tried Mastercam Deburr yet, you’re missing out on additional features and benefits. Mastercam Deburr seamlessly integrates into your existing Mastercam setup.

It offers a comprehensive solution for deburring and edge treatments, which removes burrs—small, often sharp, imperfections that can occur on the edges of machined parts.

Burrs can complicate machining, affect workpiece placement, and reduce finish quality. Mastercam Deburr provides a smoother operation and superior end-finish quality.

What’s New?

Check out our recent 4-part video series to see why you need Mastercam Deburr:

How Mastercam Deburr Saves Time and Optimizes Workflow

Check out Chad and Jesse going head-to-head in a deburring competition using Mastercam, pitting Mastercam Deburr against traditional Model Chamfer & Contour Chamfer methods. See which method delivers better results in less time.

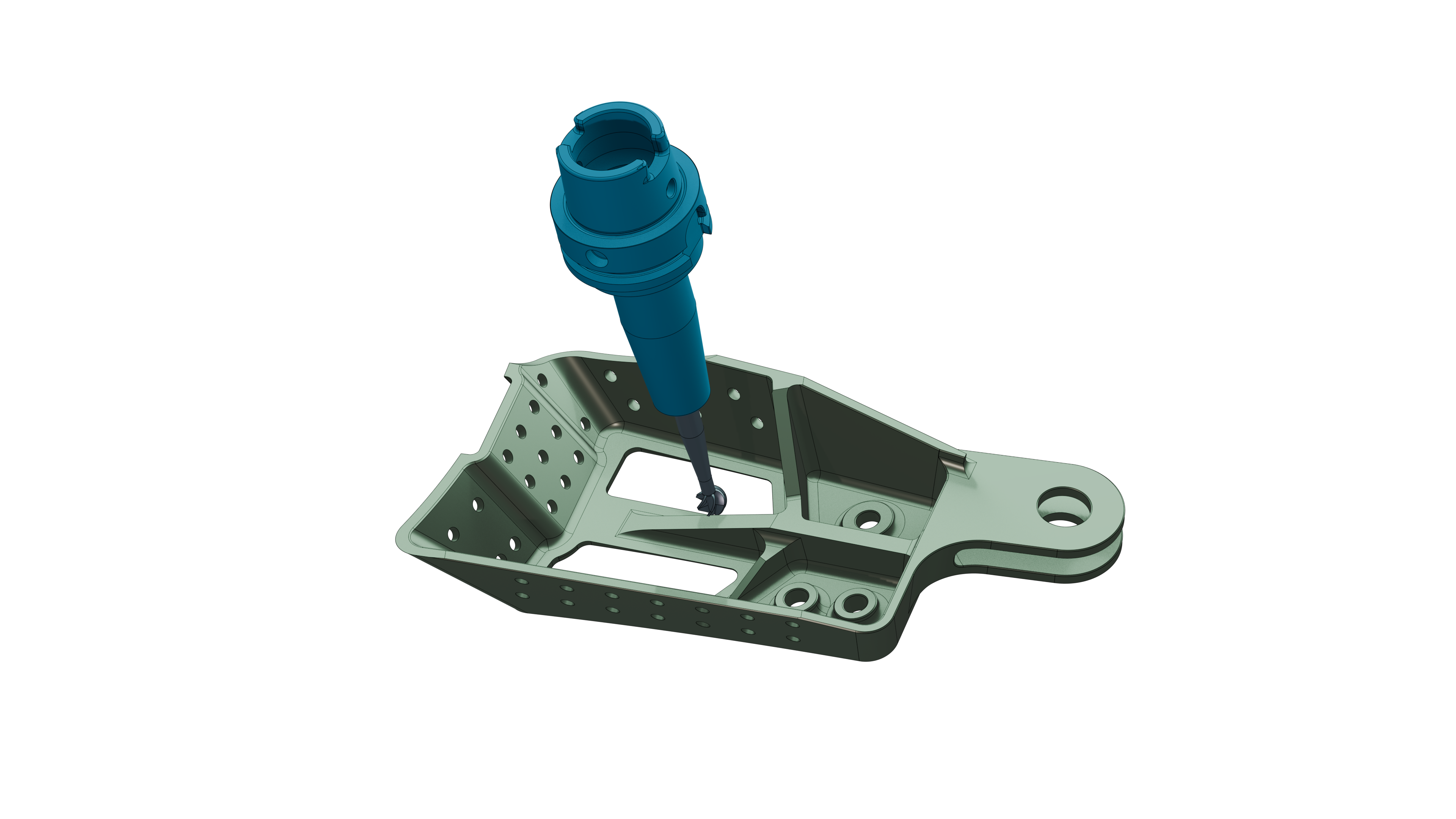

Using Mastercam Deburr to Perform Complex Undercuts

Dive deep into what makes Mastercam Deburr a game-changer for machine shops everywhere. Whether you’re deburring standard edges or tackling intricate 3-axis undercut geometries, Mastercam Deburr has you covered.

How to Achieve Superior Accuracy with Mastercam Deburr

Compared to traditional contour toolpaths, Mastercam Deburr offers uniform edges, even on complex geometries, superior accuracy on sloped surfaces, and safer, collision-free toolpaths with fewer manual adjustments. Find out why Mastercam Deburr is the ultimate tool for precision, efficiency, and safety.

Collision Avoidance with Mastercam Deburr

Mastercam Deburr takes the hassle out of deburring and chamfering with automatic compensation for part geometry, eliminating collisions, safer and more precise toolpaths for perfect finishes, and a faster, smarter workflow for even the most complex parts. If you’re tired of manually adjusting toolpaths and wasting time, Mastercam Deburr is the solution your shop needs.

Key Benefits of Mastercam Deburr:

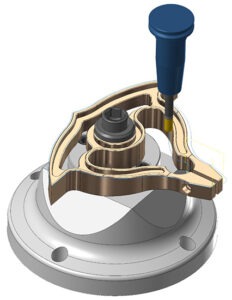

- Time and Resource Savings: Reduce manual labor and benefit from reduced programming time from automatic edge detection.

- Tool Compatibility: Supports Chamfer, Dove Mill, Ball Mill, Lollipop Mill, and Taper Mill with Full Radius tools across multiple machining strategies.

- Easy Integration: Available with Mastercam 2D and 3D Mill, Router, or Mill-Turn products.

- Enhanced Productivity: By deburring parts directly on the machine, Mastercam Deburr reduces processing time and improves overall efficiency.

- User-Friendly Controls: The intuitive interface allows users to manage deburring tasks with ease, reducing the learning curve and increasing productivity.

Ready to take your deburring process to the next level? Connect with a Mastercam Channel Partner and learn more about Mastercam Deburr can revolutionize your machining operations.