If CNC turning is slightly less understood than CNC milling, CNC mill-turn can be an utter mystery to many. Just about any machine shop you encounter will have some combination of milling machines and lathes, but a Mill-Turn center can be more rare. The reason is because mill-turn is more specialized and less widely used than both. But that isn’t to say that mill-turn can’t outclass both when the situation is right. In this blog, we will go over the differences among milling, turning, and mill-turn as well as when you should use each.

What is Mill-Turn?

Mill-turn is most often used as a label for a CNC machining center. There are CNC milling centers, CNC turning centers (CNC lathes), and CNC mill-turn centers. Mill-turn can also refer to the type of machining a CNC mill-turn center uses. Milling & turning, mill-turning, mill/turn, and mill-turn can all be used interchangeably.

First, let’s look at a mill-turn machine. A mill-turn center will be set up in such a way that both the workpiece and the cutting tool can be rotated, sometimes simultaneously. Oftentimes, the mill-turn center will have multiple spindles that the workpiece can be passed between or among. As such, mill-turn centers are often larger and more complex-looking than their milling or lathe counterparts. The main differences among most mill-turn machines are the maximum size material that they can manipulate (determined by axis travel and overall unit size) and the number of machinable axes they offer (usually up to nine).

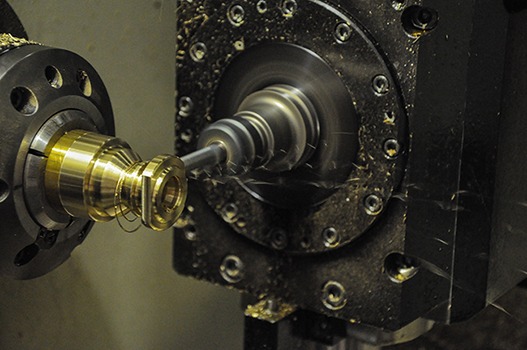

Now, let’s analyze the mill-turn process. Mill-turn essentially merges milling and turning operations into one for faster, more efficient machining. Milling relies on a rotating cutting tool that advances into the workpiece to cut away material. Turning relies on a rotating workpiece that a stationary cutting tool advance into. Thus, mill-turn rotates both the cutting tool and the workpiece according to a part’s specific shape and the tools being used.

When should you use mill-turning?

Any time you need to move a part from a lathe to a mill, or vice-versa, you lose efficiency. Not only does it take extra time to program two different machines, to move and re-fixture the part, and to stay close and available during these shorter machining times, it also introduces much more chance for human error. Mill-turn is the obvious solution for these types of parts.

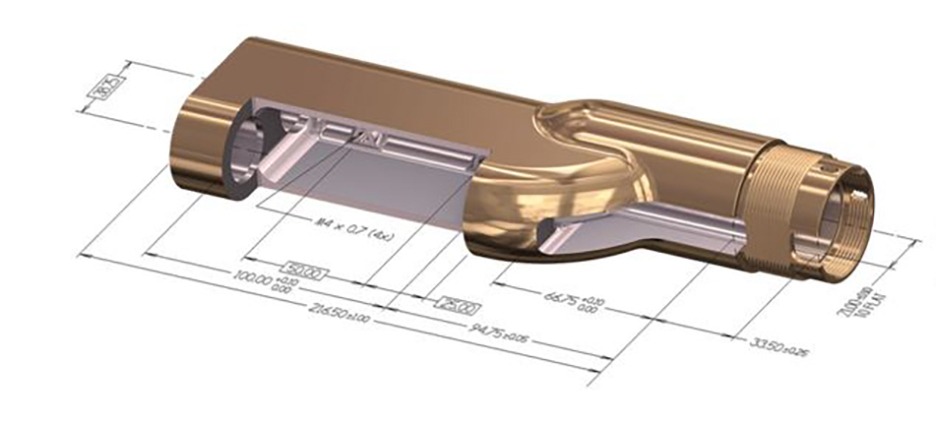

The parts that are often mill-turned are those that are slightly more complex than most, often automotive, aerospace, or medical components. Many of the parts within engines and medical implants are created with mill-turn, because they have aspects that need to be turned as well as milled. To maintain the quality expected of those parts, their manufacturers have to use mill-turn.

Imagine you were going to machine a part very similar to a flute. The part is largely cylindrical, but it has holes, finger rests, a mouthpiece, etc. It may even have an etched design on its surface. With mill-turn, you could program the machine to turn the workpiece until the flute’s cylindrical shape was carved out before milling out the details. Some centers maybe even be able to do both at once!

When should you use CNC milling or CNC turning instead?

For those shops that haven’t yet invested in mill-turn, don’t worry! A great deal of parts can still be machined solely on a CNC mill or on a CNC lathe.

Even today, the vast majority of parts are machined – and machined well – on CNC milling centers. That’s because mills excel with parts that have flat and “sculpted” surfaces, which most do. Take a look at the average machined part, and you will find that it is boxier than it is cylindrical. Mills handle the operations like drilling/tapping, contouring, pocketing, and surface machining that make these geometries possible.

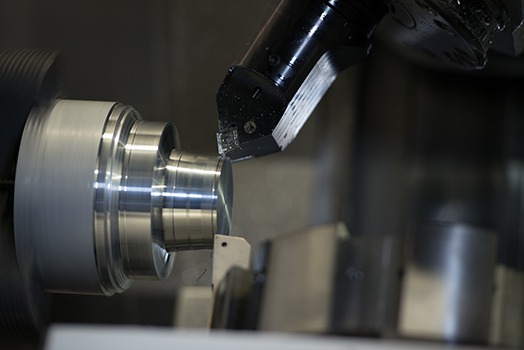

For cylindrical parts, lathes outshine mills. CNC lathes operate the same way wood lathes do: by spinning the workpiece quickly and shaving off material with a stationary cutting tool that moves into the stock. Most commonly, CNC lathes are used to make radially symmetrical parts like screws, bars, and pins.

The common denominator among all parts that do best on a milling machine or a turning machine and not a mill-turn machine is that those parts are relatively simple. They do not require both milling and turning to produce them.

The takeaway:

Many parts can be machined on one machine alone – either a CNC mill or a CNC lathe – and there is nothing wrong with that. The benefit of mill-turn lies in its ability to replace both for parts that would require milling and then turning, or turning and then milling. If you find your shop losing time and accuracy moving parts back and forth between machining centers, consider looking into mill-turn. You can even try the Mastercam Mill-Turn Solution for free with the Mastercam Learning Edition.