车铣复合编程

车铣复合编程

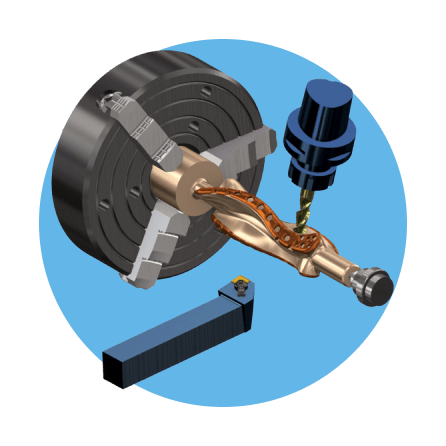

Mastercam 车铣复合编程软件简化了大功率多流加工中心的工作流程,提高机床性能和安全性。 这些多任务处理 CNC 机床减少了多次设置、零件手动处理、多余夹具和设备闲置时间,从而提高生产效率。

产品概述

经过验证的 Mastercam 铣削和车削刀路,简化了车铣复合车床的编程,其作业设置与您车间中的机床设置完全一致。

- 在单一平台中实现工作流程的优化、同步和可视化。

- 自动化编程,轻松管理多台机床数据流之间的复杂操作。

- 简化工作流程,高效完成铣削、车削和钻孔编程。

- 除了满足复杂机床的工作要求,还可以为简单车削编程。

在使用多任务加工机床时,Mastercam 车铣复合模块可在单一环境中对复杂零件进行编程并测试您的加工策略 。 使用 Mastercam车铣复合模块,可以避免碰撞,提高机床的安全性。

- 自动作业设置

- 基于毛坯智能计算刀路。

- 功能强大同步甘特图或树型操作

- 基于机床性能直观处理零件

- 更加直观的整机仿真功能

- 功能强大的 多轴 加工

Mastercam 车铣复合模块的自定义机床环境可以自动获取机床的配置和行程限制,以确保加工的安全和精度。

特征

适用于 CAM 的 CAD 设计软件

Mastercam 设计模块可满足工程师的设计需求。其功能包括线框、曲面和实体设计;支持打开大多数 Mastercam 中的 CAD 文件,帮助 CAM 编程人员快速完成建模和刀具准备,以便进行零件的装卸。

先进技术

Mastercam 经验证的刀路、零件直观处理、自动作业设置、3D 刀具支持、用于优化车铣复合加工的定制铣削刀具、去除毛刺、支持 2 到 5 轴刀路加工、多刀塔、多主轴等操作,可以全部在一个机床环境中进行管理。

先进的刀路

将代码发送到机床之前,检测毛胚、刀具和机床组件之间的碰撞。 “机床模拟”是验证 3 轴、4 轴或 5 轴刀路可以生成简洁、高效和准确程序的安全方法。

Mastercam Code Expert 代码专家

利用这一最先进的界面,优化刀塔和主轴之间的机床移动和同步,以生成准确而高效的代码。

通过专有的刀路策略延长刀具使用寿命,最大限度地提高材料去除率并缩短生产周期。

灵活性

Mastercam 车铣复合模块提供完整的后处理,为这些机床(如夹持和平衡车削)制造额外的刀具,并简易实用于双主轴、双刀塔和 B 轴机床。

优点

作为山特维克集团的一部分,Mastercam 车铣复合软件的用户可以受益行业领先技术,例如 PrimeTurning™ 自动刀路策略和 CoroTurn® 刀具。

插件

案例研究 View all

3D-Machine, Inc.

New CAM toolpath cuts hoist drum production time by 83 percent Before using Mastercam Lathe Custom Thread toolpath, producing a hoist drum—including machine set up, tooling, and machining—took at least 40 hours. With the CAM toolpath, 3D-Machine, Inc. produced the part in just seven hours. Quick Facts Product Used: Mill, Mill-Turn, Lathe, Multiaxis Industry: Tool…

Achates Power

Complex Machining Replaces Casting for Two-Piece Components in Piston Prototypes Achates Power in San Diego, California, uses Mastercam to create prototype parts for an eco-friendly, gasoline compression ignition, opposed-piston engine. The collaborative research was the work of Achates, Argonne National Laboratory, and Delphi Technologies. It was produced using funding from the U.S. Department of Energy’s…

Mastercam 社区

当您选用世界上广泛应用的 CAM 时,您获得的好处远远超过驱动我们软件的技术。 由 Mastercam 用户、专家、教育工作者和爱好者组成的全球社区可以帮助您从投资中获得高回报。

FAQs

A mill-turning machine performs subtractive manufacturing, where material is removed through strategic cutting techniques. On a mill-turning machine you have the capabilities of a mill, where the tools move around a piece of stationary stock material, combined with the capabilities of a lathe, where the tools move on a spinning piece of stock. A CNC mill-turning machine is capable of cutting parts as programmed by a CAM software like Mastercam.

关闭A CNC mill-turn machine is programmed like all computer numerical control machines, with a CAM software. Software such as Mastercam is used to create efficient machine motion using G-code to program the CNC mill-turning machine and automate the manufacturing process.

关闭CNC milling is a subtractive manufacturing process where the tools move around a stationary piece of stock material that is held in place with a variety of fixturing options. In CNC turning, material is similarly removed from a piece of stock material, but instead of being stationary, it is spinning in a lathe assembly.

关闭It is difficult to identify a disadvantage to a milling machine unless your manufacturing process would benefit from a different type of machine altogether, such as a lathe, mill-turn machine, or Wire/EDM machine, for example. This cost of investing in a CNC milling machine may seem like a disadvantage compared to a manual mill. However, it is likely the added machining capability and increased productivity and efficiency benefits will so quickly compensate for the initial investment that the cost is not truly limiting as a disadvantage.

关闭Mill-turning machines introduce complexity not seen in many other milling machines or lathes. Mill-turning machines often include multiple turrets with different tools, some of which can engage the part at the same time. For this reason, the most important aspects of safe and efficient mill-turn programming are 1) robust mill and lathe programming techniques, and 2) the ability to properly synchronize tool motion from multiple locations.

关闭CNC mill-turning software eliminates errors that can occur when manually programming a CNC mill-turning machine. It also allows adaptability and offers methods of precision machining that are impossible through manual programming.

关闭